2019.12.06

GIST (President Kiseon Kim) School of Materials Science and Engineering Professor Kwanghee Lee's research team has developed a microcavity OLED structure * for sensitive lighting using a simple thin metal transparent electrode.

With this research result, it is expected to produce various kinds of sensitive lighting with a simple device structure and accessible in real life.

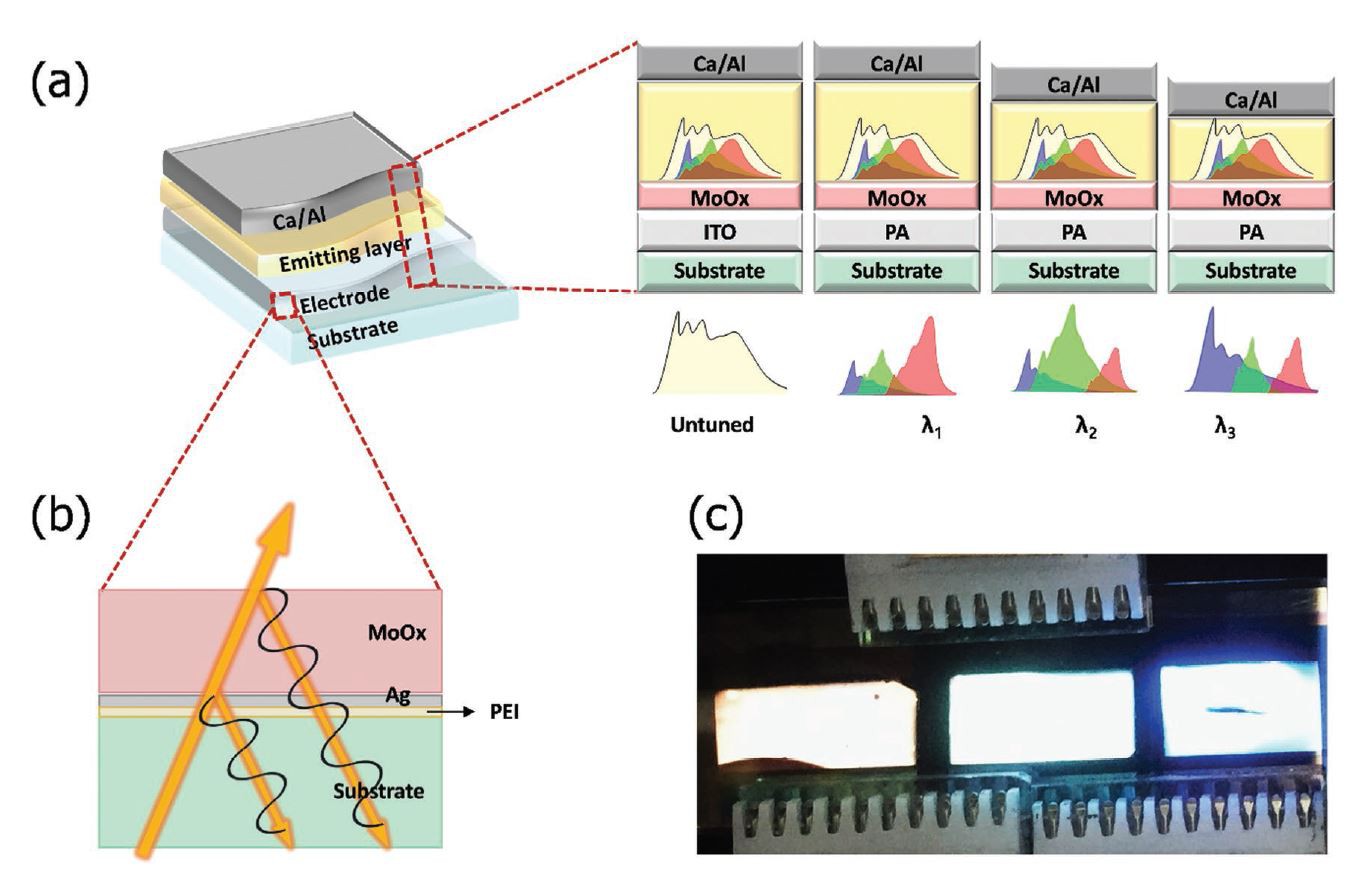

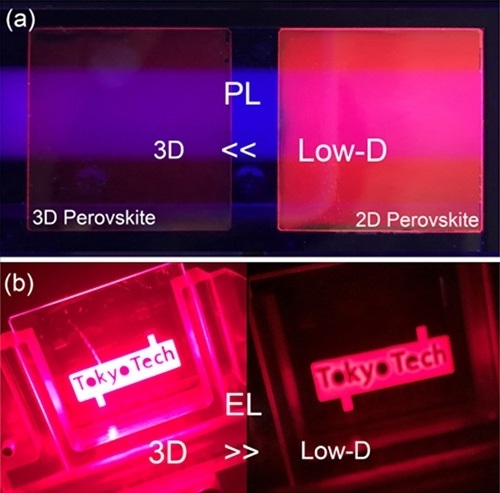

The microcavity structure is a method of improving the emission rate of light by using the fine vibration effect of light (wave reinforcement interference and offset interference). It is mainly used for converting the emission color of OLED. However, the existing microcavity structure has to be manufactured separately on the outside of the device, which is disadvantageous in that the process is cumbersome.

The research team developed the microcavity OLED structure without introducing a separate structure by using ultra-thin metal-based transparent electrode produced by MSWAY *, a flexible transparent electrode manufacturer.

Unlike other transparent electrodes, ultra-thin metal-based transparent electrodes have the advantage of being able to simultaneously play the role of a transparent electrode and a reflective layer that is part of the microcavity structure. The research team found that the color coordinates of the OLED can be effectively controlled by controlling the thickness of the organic light emitting layer of the microcavity OLED using the ultra-thin metal transparent electrode.

Professor Kwanghee Lee said, "This latest achievement is a combination of ultrathin metal transparent electrode manufacturing technology and OLED manufacturing technology that demonstrates effective microcavity structure through minimal processes. As it is a technology developed through industryuniversity cooperation, it is expected to be applied to next-generation electronic devices for sensitive lighting in a short time."

This research was led by GIST School of Materials Science and Engineering Professor Kwanghee Lee and Research Institute for Solar and Sustainable Energies Professor Hongkyu Kang and conducted by Ph.D. students Soyeong Jeong and Suhyun Jung with support from a GIST Research Institute grant funded by the GIST in 2018, the National Research Foundation of Korea funded by the Ministry of Science, ICT & Planning, the Korea Institute of Energy Technology Evaluation and Planning, the Ministry of Trade, Industry and Energy of the Republic of Korea, the Korea Evaluation Institute of Industrial Technology, and the Ministry of Trade, Industry & Energy and was published in the internationally renowned international journal Advanced Optical Materials on November 13, 2019.

* This structure consists of two reflective layers and one intermediate layer with a large difference in refractive index. The light waves cause constructive or destructive interference depending on the thickness of the intermediate layer

* manufacturer of organic solar cells, smart films, smart windows, electrode customization for OLED, and MCU semiconductors