March 19, 2020

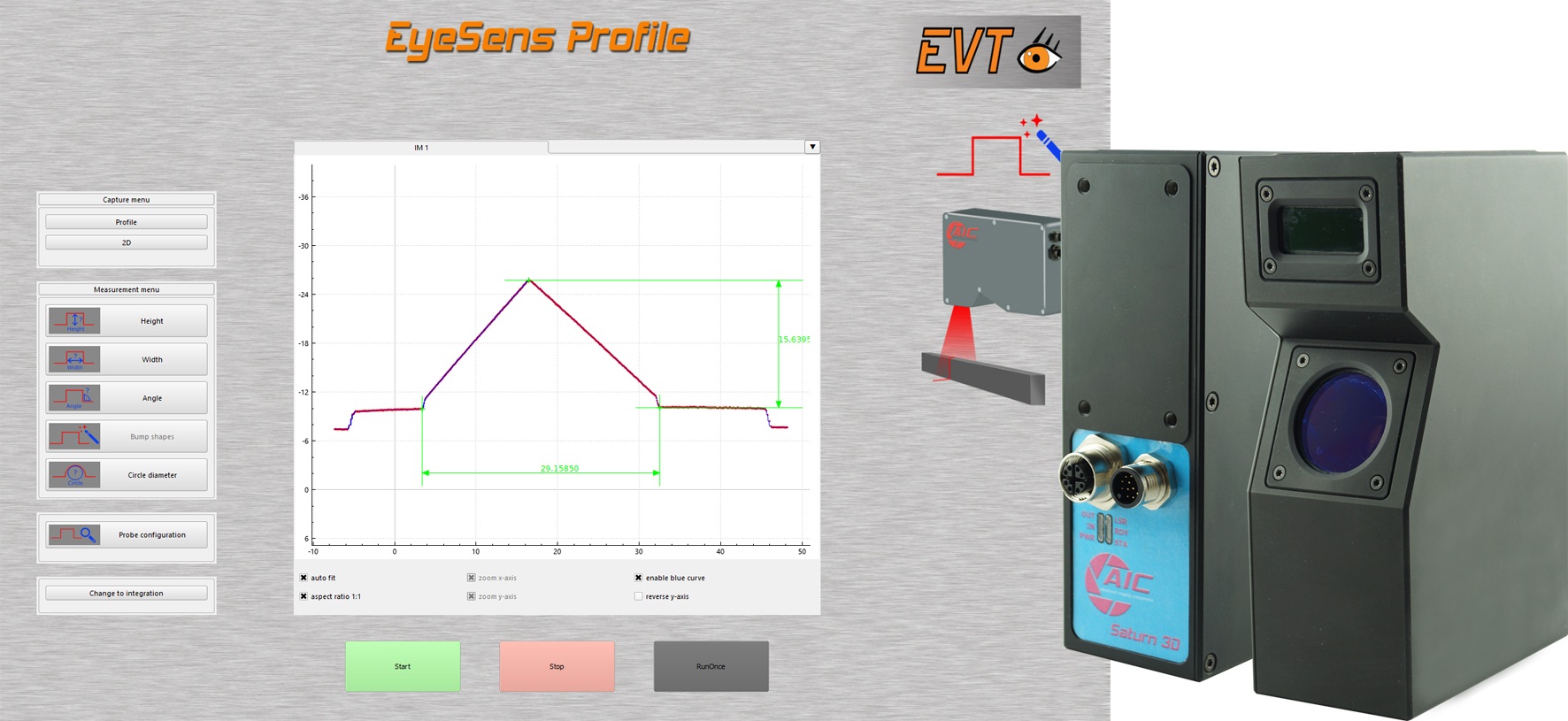

The smart EyeSens 3D Profile Inspector allows the single-button training of various profiles. Therefore, the profile can be inspected for correctness with repeatable accuracy. Most applications can be realized in the profile production field.

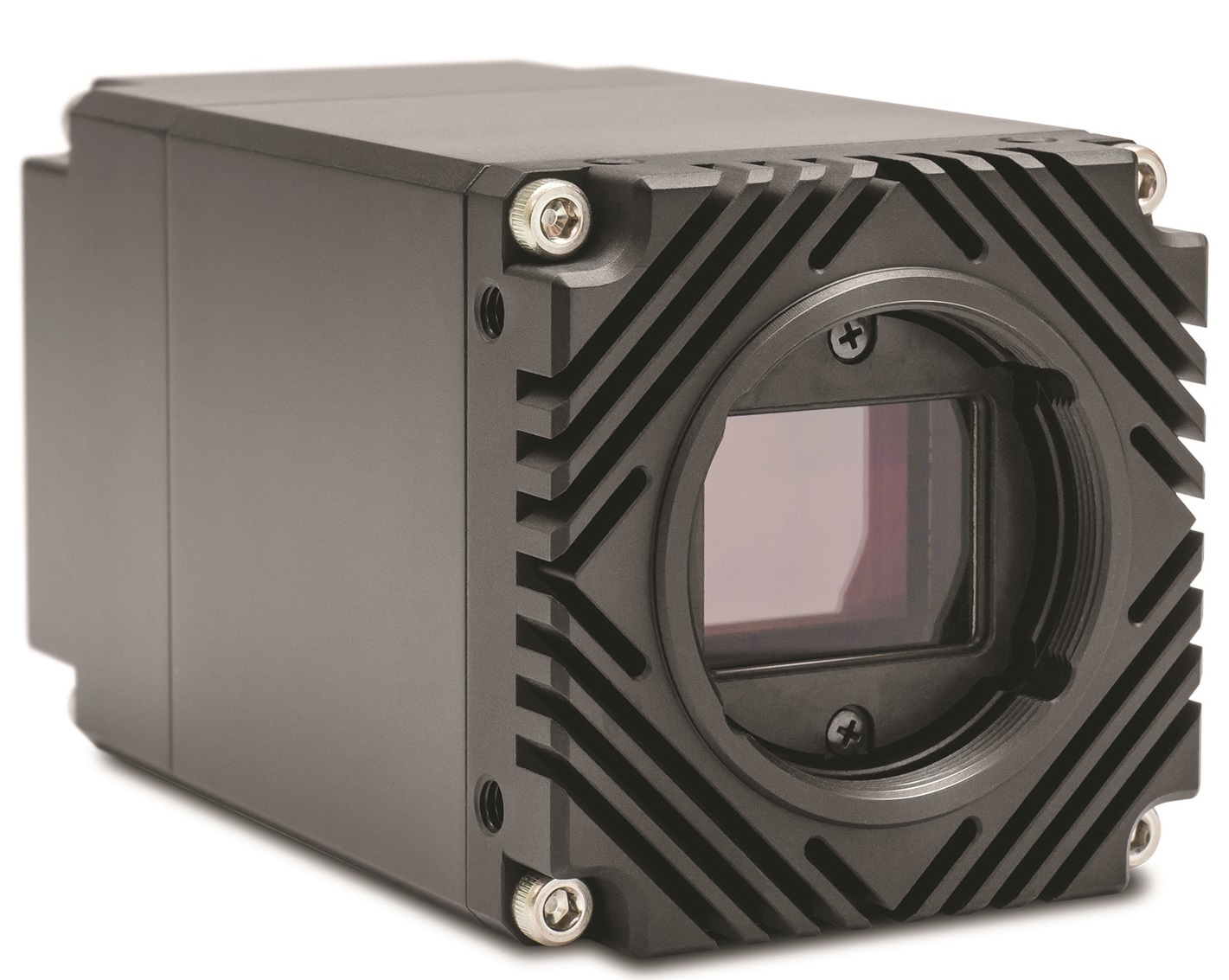

EyeSens 3D Profile runs completely without a PC, as the evaluation is carried out on the sensor. The included DualSpeed CPU board is available as 800 MHz or 1.6 GHz variation with Dual Core and open FPGA, which the user can program themselves with the included IP-Core.

The integrated EyeVision Software also includes ready-made applications such as e.g. the Bent-Sensor, Glue-and-Seal-Sensor, Gap-Sensor, WeldSeam Sensor, and many more. The application, as well as the evaluation runs on the sensor, without a PC.

Thanks to the integrated EyeVision software the PC-less EyeSens 3D Profile Inspector has a Profinet interface to connect the system easily to a PLC. Further communications interfaces such as Modbus, TCP/IP, UDP, etc. are also available. Also, an OPC UA communication with a SCADA system is possible.

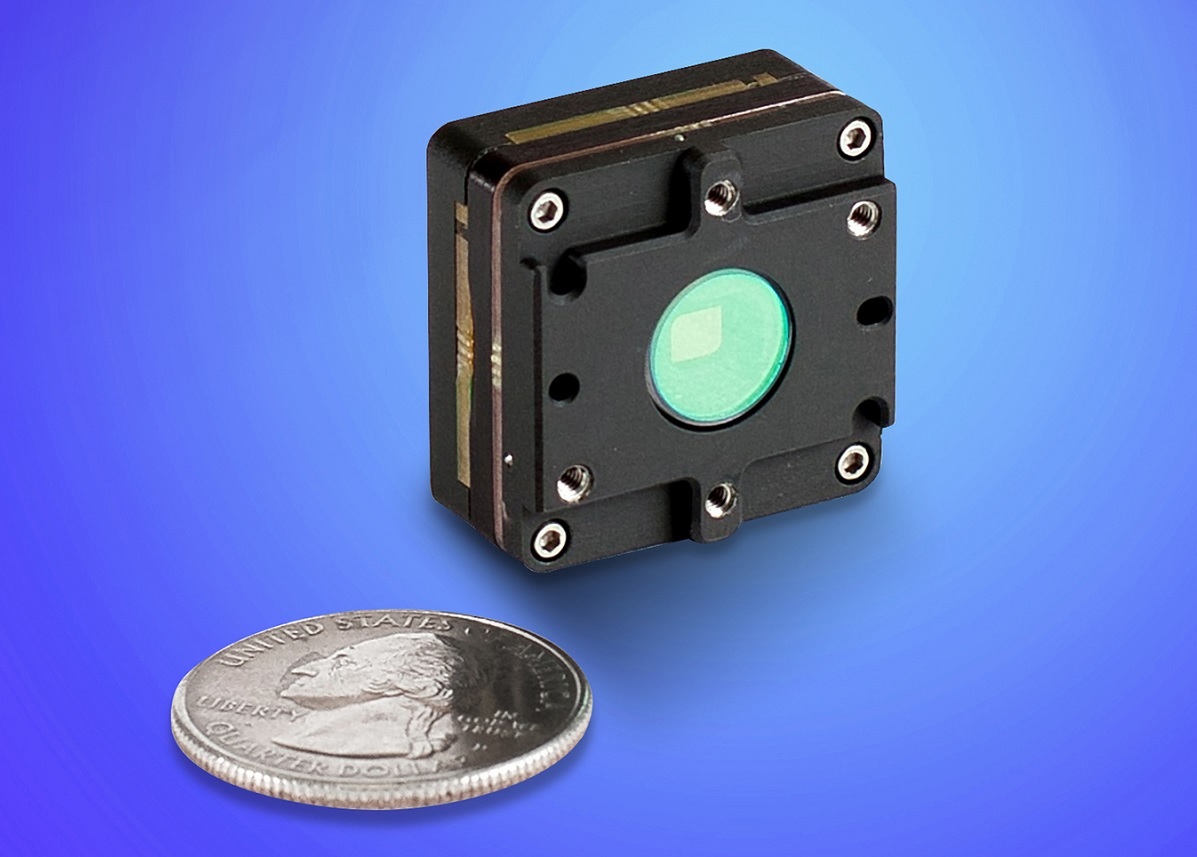

The extremely compact and innovative 3D laser triangulation sensor has a Power over Ethernet (PoE) interface, an encoder interface and with a profile speed of up to 6 kHz the sensor is ideal for high-precision 3D profiling. The triangulation sensor is available with different lasers, with red as well as blue laser, depending on customer wishes.

With the Single-Button Training function the user also has the possibility to integrate further inspections. For the profile inspection the inspected profile is compared to a taught in profile or golden part. Furthermore, there can be carried out measurements to additionally assure functional dimensions. For example, when inspecting a windscreen wiper, the shape can be inspected and in addition the angle and the width on the wiper lip can be also measured.

The number of inspections is not limited, which means that the user is free to add any number of measurements. The programming of the measurement and inspection tasks is carried out completely graphically or with the Single-Button Training with the golden part.