April 18, 2019

Hamamatsu Photonics has established technology for efficiently cooling a laser medium and developed an industrial pulsed laser system that produces a pulse energy of 117 joules - the world’s highest among laser-diode-pumped (hereafter LD-pumped) lasers. This newly developed laser system will further enhance the laser peening effect for hardening the surfaces of metal materials used in aircraft and automobiles. This laser system will also prove a powerful assist for new laser processing applications such as laser forming for shaping metal materials and paint removal.

This laser system was developed by the “Research and Development of Next Generation Laser Processing Technology” project supported by the New Energy and Industrial Technology Development Organization (NEDO), which is a national research and development agency in Japan.

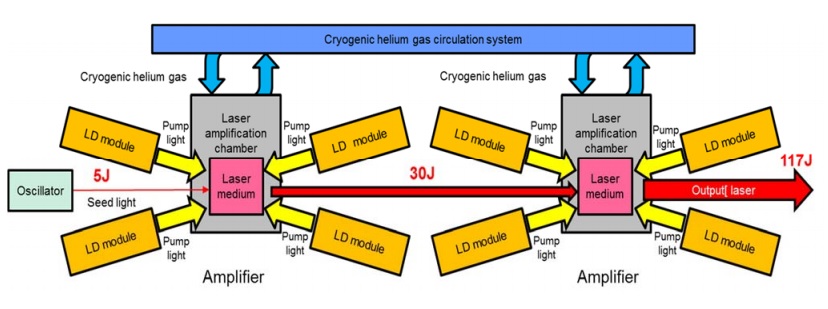

How laser energy is amplified

A laser system mainly consists of an oscillator and amplifier. When laser emitted from the oscillator passes through the amplifier, it receives energy from the pumped laser medium in the amplifier to boost the output power.

The newly developed laser system irradiates seed light into the laser medium pumped by LD modules to amplify the energy to a high output level.

Lasers are used in a wide range of processing and machining applications such as for strengthening, welding and cutting metal materials. Lasers are broadly classified into two groups: CW (continuous wave) lasers that continuously emit light at a constant intensity and pulsed lasers that repetitively emit pulsed light at very short time intervals. CW lasers are used for heat treatment such as laser welding and cutting, making them a mainstream tool for laser processing and machining. Pulsed lasers on the other hand are finding widespread use in laser peening applications for hardening the surface of metal materials by applying shock waves generated by instantaneous irradiation of high energy light pulses. Pulsed lasers with an output energy of around 10 joules are now starting to appear on production lines. For these tasks there is now increasing demand for higher energy pulsed laser systems that can irradiate a wide area and apply a shock wave deep into materials to further boost the laser peening effect.

Amplifier structure of pulsed laser system

The newly developed laser is an industrial pulsed laser system capable of boosting the pulse energy of seed light of 5 joules up to 117 joules by using two amplifiers, each of which is equipped with 4 pumping LD modules that we manufacture in-house.

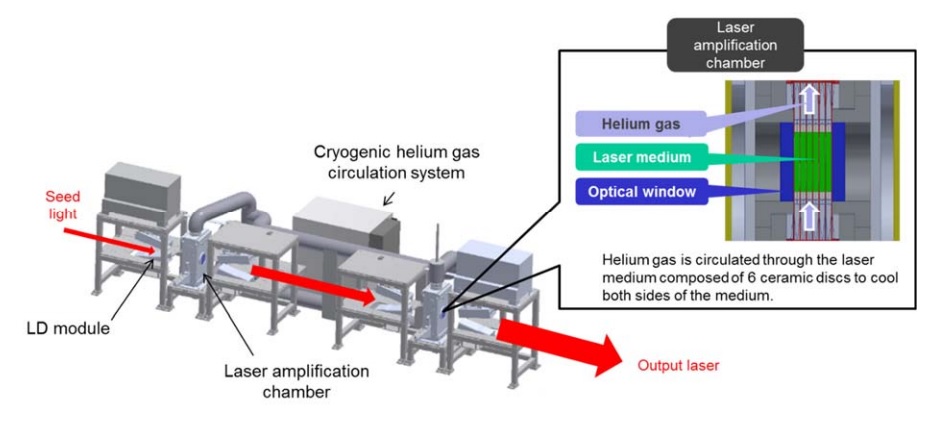

Hamamatsu Photonics has already been working on developing LD-pumped high-energy pulsed lasers for research applications. Now, by using the laser amplification chambers they newly developed, they have established technology for efficiently cooling the laser medium in the laser amplification chambers. The result was the world’s highest output energy among LD-pumped lasers!

To enhance laser output energy, the laser medium must be efficiently cooled. This newly developed laser has vastly improved cooling efficiency achieved via a cooling mechanism that cools both sides of the laser medium by circulating helium gas through the laser amplification chamber. The helium gas is maintained at a pressure of 5 atmospheres and a temperature of -100 degrees Celsius (-148 degrees Fahrenheit) for stable cooling. Moreover, in the optical window through which the laser passes, we employed a material resistant to low temperature and high pressures as well as a structural design with high durability.

To make the laser medium store more energy with higher efficiency than conventional devices, we newly designed large-diameter ceramic discs optimized to easily absorb light and incorporated 6 of these discs as the laser medium. We also came up with a unique amplifier design while mounting our compact yet high power LD modules as pumping sources and in this way succeeded in downsizing the system. This means we can now provide a LD-pumped pulsed laser system capable of producing the world’s highest output energy, even with a device footprint equivalent to LD-pumped pulsed lasers developed overseas.

This newly developed laser system will further enhance the laser peening effect because laser light irradiated onto a metal material applies a shock wave into deeper parts of that material. Applying this laser system as a laser processing platform in cooperation with the TACMI Consortium will promote new laser processing applications such as laser forming and paint removal.

Hamamatsu Photonics has will continue developing new laser media and cooling techniques to further boost the laser output energy. In cooperation with the TACMI Consortium and, along with member companies and other companies involved in laser processing, they will open up new laser processing applications by continually creating practical laser processing technology.