Zurich, August, 2014 – Optotune presents a new laser processing lens with optical feedback. While compactness, fast response and long life cycle have been well known benefits of our technology for laser marking, the new optical feedback system allows for precise focal length control over a wide temperature range. At LASYS in Stuttgart at the end of June 2014, the new laser processing lens EL-10-42-LP has been demonstrated in an actual laser marking system. Product launch is expected in September 2014.

Benefits of laser processing with tunable lenses

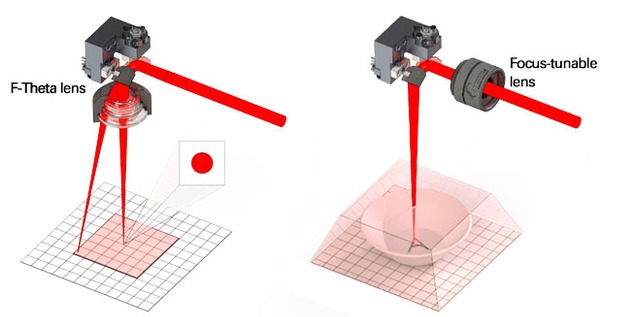

Instead of using complex translational mechanics or expensive F-theta lenses, the zposition of a laser spot can be controlled by using Optotune’s electrically focus tunable lens. In combination with galvo scanners, large scan volumes, small spot sizes and true 3D marking can be achieved.

The EL-10-42-LP features fast response times in the range of milliseconds, enabling true 3D laser processing and fast and precise switching between different marking surfaces. Furthermore, by having less moving parts, the overall system becomes more compact, reliable and less expensive. In addition, the marking area can be increased and the achievable spot size reduced, compared to systems using F-Theta lenses. The large focus tuning range of Optotune’s lenses also enables unparalleled marking volumes. Optotune’s lenses are made with proprietary materials, which have a damage threshold of >10kW/cm2 @532nm or 1064nm.

About Optotune

Optotune®, Inc, develops and manufactures adaptive optical components based on elastic polymers. Optotune’s focus-tunable lenses and laser speckle reducers offer new solutions for several industries including mobile phone cameras, machine vision, laser processing, ophthalmology and laser projection. www.optotune.com