Puchheim, Germany – September 11, 2014 – SCANLAB AG underscores its innovation leadership in laser positioning and deflection systems by setting new standards for galvanometer scanners. It is well-established that digital encoder systems offer the highest precision for laser processing. A digital encoding innovation by SCANLAB can now remove existing limitations to dynamic performance. This new approach to digital position detection substantially lowers the moments of inertia of the drives in high-precision semiconductor processing or micro-structuring. The new encoder technology is already featured in SCANLAB's dynAXISse galvanometer scanner units, as well as in the ultra-high-performance intelliSCANse 2D scan systems.

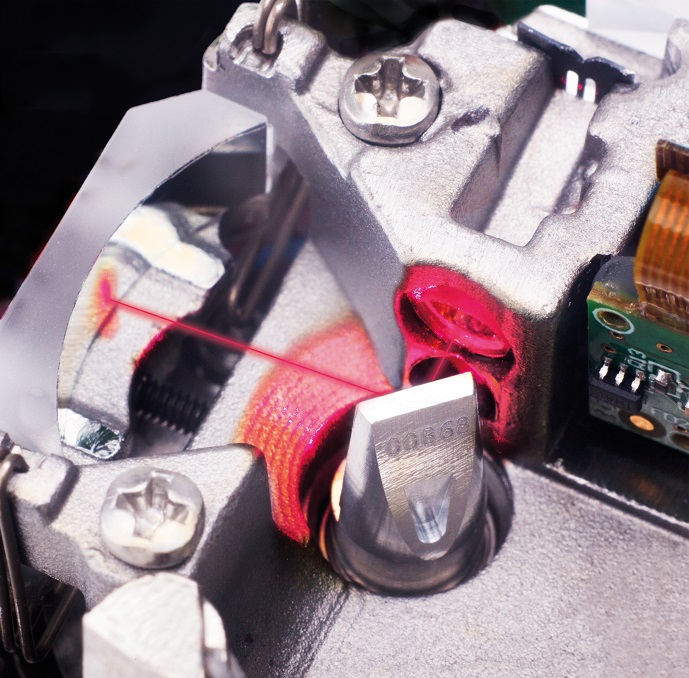

Laser processing systems use galvanometer scanners as highly dynamic drives to precisely position the laser onto a workpiece. Mirrors mounted on the galvos allow the laser beam to be precisely positioned for the particular application. Core components are a galvo motor (based on moving magnets) and a position detector. Until now, digital position detectors sensed a scale coded on a disc which is bonded to the scanner rotor. But this "classic" encoder technology limits dynamic performance, because measurement requires moving a (relatively) large inertial mass.

With its patented digital se-encoder (SCANLAB encoder), SCANLAB succeeds in removing the existing limitations to dynamic performance – while simultaneously achieving highest precision. In a minute space, the se-encoder uses a zero-mass laser beam to sense a stationary scale, much as the hands of a clock. Here, additional inertia-increasing components are no longer necessary. Furthermore, this micro-optical sensing is as reliable and refined as a Swiss watch.

New Possibilities for Microprocessing

SCANLAB's extensive technical expertise, in-house R&D and manufacturing know-how give it unrestricted ability to develop scan systems, and further customize them. Digital encoder technology is particularly advantageous for industrial applications involving semiconductor lithography, micro-structuring, and processing of electronics and displays.

"With this new sensor technology, we have succeeded in combining the speed of analog systems with the precision of digital control" says SCANLAB's CTO Norbert Petschik in describing the achievement. "Equipped with light-weight beryllium mirrors and a 14-mm aperture, we might deliver the fastest encoder system on today's global market." High precision is also indicated by lower position noise (dither) and stable long-term drift with only minimal reaction to temperature fluctuations. This allows fulfilling extreme accuracy requirements, and performing highly intricate processing steps such as in micro-structuring or the creation of VIA holes.

Over the past 12 months, this innovative digital se-encoder technology in singleaxis dynAXISse galvo scanners and intelliSCANse 2D scan systems has proven both its industrial suitability and excellent cost-effectiveness.

More information at: