Starnberg, 15th January 2014: With several hundred successful installations worldwide, ROFIN's 4-axes precision laser cutting system StarCut Tube continues to set the benchmark. It's the first choice for high-precision processing of tube material for medical implants (e.g. stents) and instruments (e.g. endoscopes) and various other tube and sheet material applications in the automotive and aerospace industry, just to name a few. Recently, ROFIN revised the current 5th StarCut Tube generation and added several improvements.

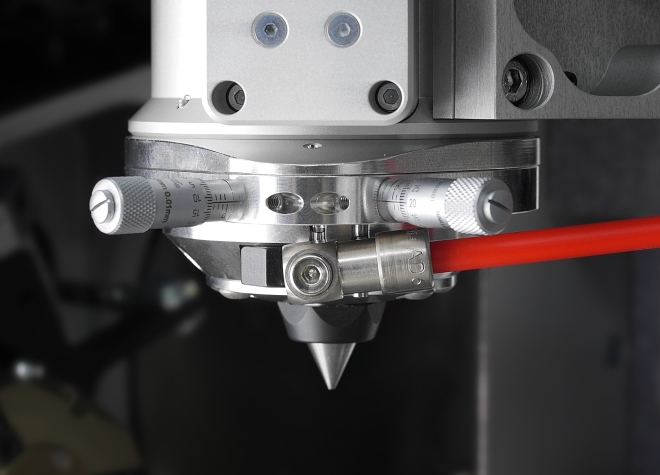

New high-precision cutting head

The new high-precision cutting head BAK-MC features excellent optical properties. It now allows to micro-adjust the assist gas nozzle in the x/y plane without changing the beam guidance. With the integrated drawer, changing the protective glass is a breeze and requires no dismantling.

Larger working chamber, part removal at any time

Offering a width of 600 mm, the enlarged working chamber provides enough room for long parts and/or customer-specific handlings. A drawer allows to remove finished parts at any time during ongoing production - even during wet-cutting. If 600 mm are not enough, for instance for hypo-tube cutting, the automatic part removal system can be added.

StarCut Tube with larger working chamber