August 28, 2013

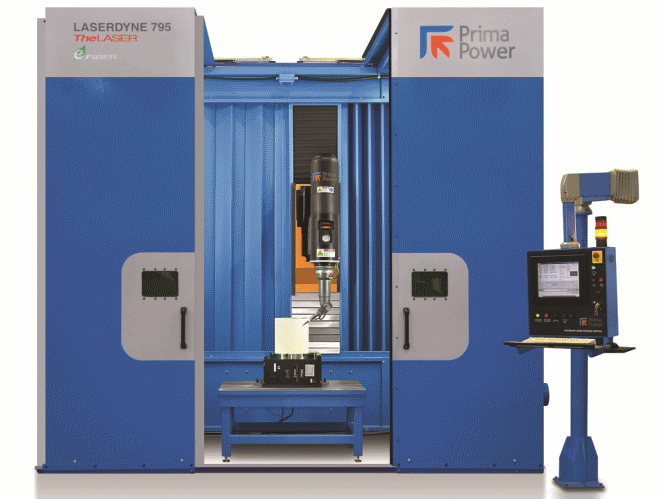

Champlin, Minnesota: Prima Power Laserdyne, the world leader in precision multi-axis laser machining systems, announced that Hi-Tek Manufacturing, Mason, Ohio, acquired the large work envelope version of the high accuracy LASERDYNE 795XL laser system.

Hi-Tek manufactures highly engineered, complex components and assemblies for aircraft engine, airframes and land based industrial gas turbines. The acquisition of the new fiber laser system expands Hi-Tek’s laser processing capabilities for these components and assemblies, most of which are fabricated from difficult to machine high temperature alloy materials. “The LASERDYNE 795XL system with a fiber laser can be a real “value creator” for Hi- Tek Manufacturing, achieving superior results both in higher productivity and lower operating costs.” reports Mark Barry, Vice President of Sales for Laserdyne. “The new system allows Hi- Tek to go beyond its present capabilities while adding capacity for hole drilling at very low angles to the surface in uncoated and thermal barrier coated heat resistant materials. This is extremely important in the turbine engine industry for production of both land based turbine engines and aero engines. This increased productivity is accomplished because of the new advantages of both the fiber laser and the system’s third generation BeamDirector®3 features.”

Scott Stang, Manufacturing Technology Manager at Hi-Tek Manufacturing reports, “This acquisition is the result of our never ending effort to procure the best manufacturing solutions for our customers. For 33 years Hi-Tek has been providing the most advanced manufacturing capabilities for Cooling Hole Drilling, CNC Grinding, Machining, Engineering, Tool and Gage Design, Welding, and Assembly. We are scheduled to have Vacuum Braze and Heat Treating in-house capabilities late in 2013. Hi-Tek now has eleven laser processing systems, both Nd:Yag and CO2, for processing a wide variety of complex parts, from low to high volume production.”

The LASERDYNE 795XL integrates a 12kW fiber laser, significantly improving drilling and cutting applications over earlier systems for selected applications. In addition, fiber laser technology is more energy efficient, requiring lower input power for a given level of average output power and less cooling.

The BeamDirector®3 used in Hi-Tek’s new system has the exclusive LASERDYNE contouring head design with C (rotary) axis motion of 900 degrees, and D (tilt) axis motion of 300 degrees. Among its many features are a new design of encoder for improved accuracy and repeatability, higher assist gas air-flow, adjustable mirrors for easy and accurate beam alignment, and cassette mounted lens and cover slides for quick, accurate changeover.

In addition to drilling, Hi-Tek’s new 3D – 6 axis laser system is designed to cut and weld medium to large 3D parts with its unique moving beam design. It is the first and only standard built multi-axis laser system to guarantee volumetric accuracy in high-speed operation. Mr. Barry also reported that like Hi-Tek Manufacturing, “a large number of LASERDYNE customers have embraced the use of fiber laser technology for sheet metal processing with excellent results. The Prima Group was one of the first laser processing system manufacturers to utilize fiber lasers. Our approach of combining integrated motion and fiber laser process control has and will continue to yield further advances in cutting, drilling and welding processes.” Mr. Barry added, “Not only is this combination significant for aerospace manufacturing, it is important for all industries that use laser processing.”

For Laserdyne’s first ever report on fiber laser drilling, go to http://www.primapowerinterface.com/fldp/index.html.

For more information about Hi-Tek Manufacturing visit www.hitekmfg.com