30 August 2016

Traditional machine vision is morphing into an intelligent tool for production optimisation, which can take on far more than pure inspection tasks. For example, between the 8th and 10th of November, VISION, the world's leading trade fair in Stuttgart, will feature 3D technology with which users can improve logistics handling and which they can use in conjunction with data glasses for "augmented reality".

There is an increasing tendency among users to view such 3D systems as multi-functional devices to which they can entrust a plethora of tasks. According to Jana Bartels, Product Manager for 3D/ToF at Basler AG in Ahrensburg: "There is growing interest in 3D cameras, for example for process automation and monitoring, to simplify the control of robotic systems, and to optimise, and increase the security of, man-machine interfaces." Among the highlights she cites is a collaborative project between Jungheinrich AG and the Hanover Institute for Integrated Production (IPH) with Basler AG, and Götting KG as well as the Institute for Technical Computer Sciences (ITI) at the University of Lübeck (Universität zu Lübeck). This project resulted in the creation of a high-reach fork-lift truck that understands human language and uses 3D machine vision to interpret gestures. This project points the way to future communications between man and machine.

Bartels comments on a number of emerging trends: less complex 3D systems are in the pipeline incorporating faster sensors with higher resolutions, which will be easier to operate. Rather than focusing on the initial capital acquisition costs, users will be more concerned with the Total Cost of Ownership. Among other things, Basler will present cameras with an LVDS-based BCON interface for embedded vision systems and the new time-of-flight camera at the VISION trade fair. As Bartels explains: "It is the first industrial VGA camera available in the mainstream price segment that works on the ToF principal.

The new high-resolution Time-of-Flight camera makes the use of 3D technology possible even in the mid-price sector. Image: Basler

Discuss trends before they become established

Ritchie Logan, Vice President of Business Development at odos imaging limited, Edinburgh, views Industry 4.0 as an important driver for innovation in the vision sector. "Industry 4.0", he explains, "and the new 3D Time-of-Flight technology meet a wide range of user desiderata. That helps us to develop new solutions in connection with Industry 4.0 and Logistics 4.0."

As the world's largest trade fair for machine vision, VISION is extremely important to odos imaging, because, as they report: "we get the opportunity here to hear about new trends for the first time and to discuss them with customers and potential users before they become established." In addition, the VISION trade show offers good opportunities for networking with other companies within the sector. "We return home with all of these impressions and data in our luggage to get on with doing what we do best as a hardware company; developing new solutions for current challenges." With an eye on the VISION Award 2014, which the Scots won for their "Machine Vision with Depth" concept (a high-resolution system based on pulsed 3D time-of-flight imaging systems) the company will be presenting new developments such as StarForm, a high-resolution 3D ToF camera, and the StarStop event recording camera with freeze motion function.

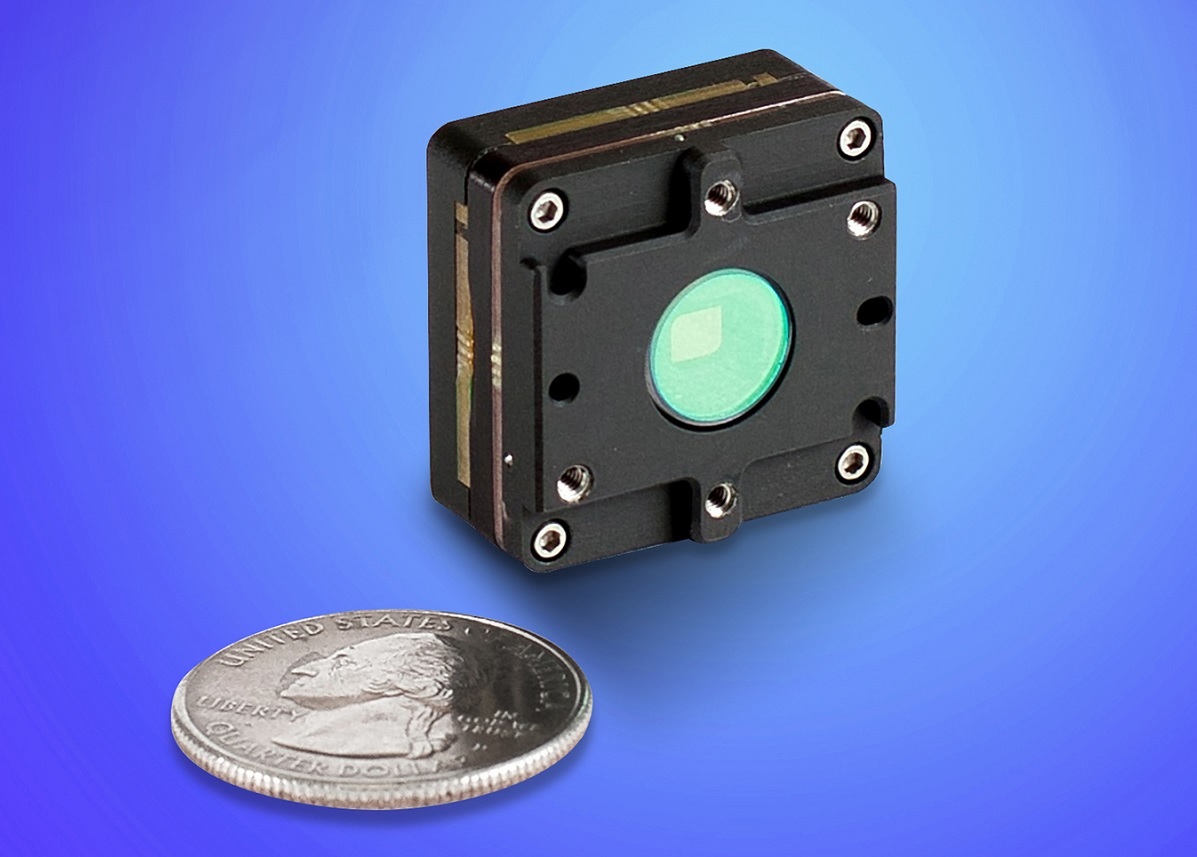

Embedded Vision System: Thanks to the BCON interface, the LVDS-based Vision technology can be realised with the board-level camera. Image: Basler

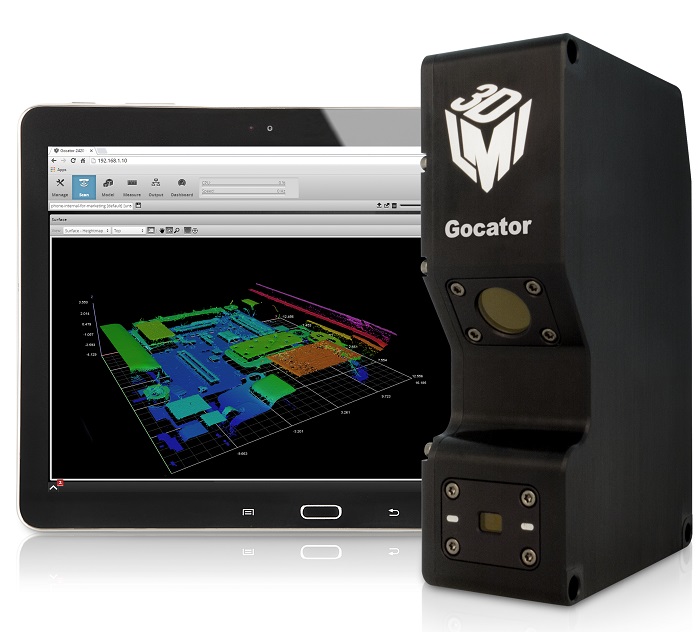

The customers of the Berlin-based LMI Technologies GmbH are particularly concerned with three significant factors: reliability, rapid and precise measurements and easy operability. "Our products are used in 100% in-line control scenarios", LMI's Managing Director, Terry Arden explains. "Our customers often use our technology in harsh environments." For that reason, the devices need to be sufficiently robust to ensure that they still perform extremely well in spite of vibrations or dust. In addition, there is a requirement for precise measurements even in the face of high production speeds. As Arden goes on to say: "Our sensors deliver a high resolution thanks to which, crucial quality features of a given component can be precisely identified and verified with a high repeatability rate." The user-friendly operation is equally important, he goes on to say. Among other things, the customers expect a simple set-up process, effective 3D visualisation of a scanned component, and drag-and-drop mensuration tools.

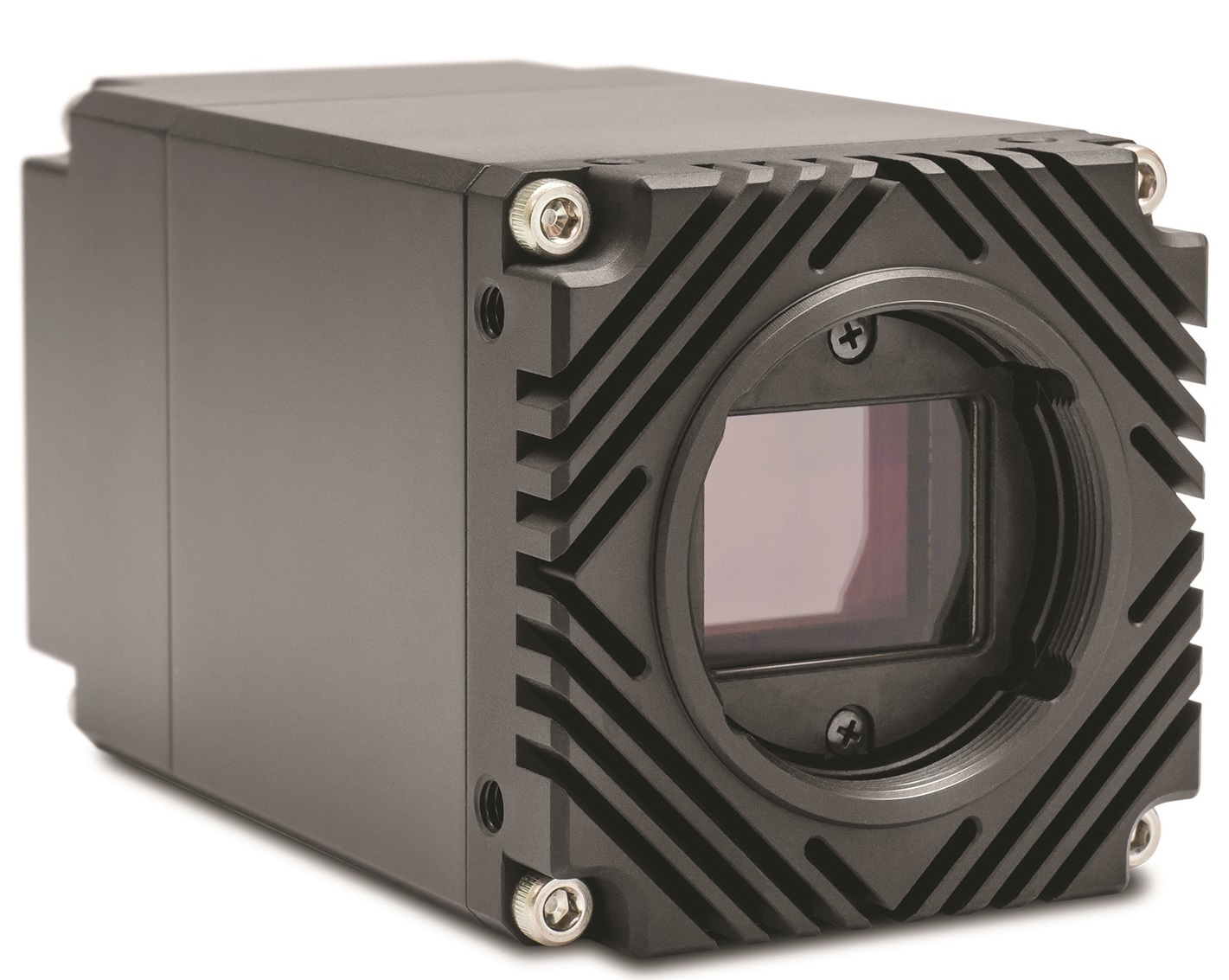

Among other things, odos imaging will be presenting the high-resolution StarForm 3D-ToF-camera and the StarStop Event-Recording camera with freeze-motion function at the VISION trade fair. Image: odos imaging

To withstand these challenges, LMI incorporates CMOS chips and embedded technology into the chips. At the VISION trade show, LMI will be presenting their most recent CMOS technology (Gocator 2410 smart 3D laser line profiler, Gocator 3506 smart 3D snapshot sensor), which, according to the company's literature offers the highest resolution within the entire sector at 2 and 5 mega pixels respectively.

Rapid Capture of Moving Objects

For the customers of Matrix Vision GmbH from Oppenweiler, the rapid acquisition of 3D data from moving objects is crucial. According to Technical Director Uwe Furtner (MEng.): "Our solution, which involves real-time 3D point cloud generation with a sufficiently high resolution level fully meets this requirement." He goes on to explain that rapid 3D data capture is also desirable because it represents a valuable addition to Industry 4.0, because of its outstanding ability to be integrated into networked environments. For quality checking purposes, he says, users can compare the CAD data directly online with the results of the calculated point clouds.

At the VISION trade fair, LMI will be presenting their most recent CMOS technology (Gocator 2410 smart 3D laser line profiler, Gocator 3506 smart 3D snapshot sensor), which, according to the company's literature offers the highest resolution within the entire sector at 2 and 5 mega pixels respectively. Image: LMI

Rather than representing a pure 3D solution, the company's mvBlueSIRIUS product, which will be on display at VISION 2016, consists of a 6D camera which provides movement vectors and RGB colour data in addition to 3D point clouds. According to the Managing Director: "In addition to a pure data calculation, our camera is able to recognise objects, which can be described in terms of data relating to shape, colour, size and velocity." The special thing about this 6D recognition is that it makes it easier for people to use who have no experience with algorithmic output analysis.