03 Nov 14

by Tore Vind Jensen

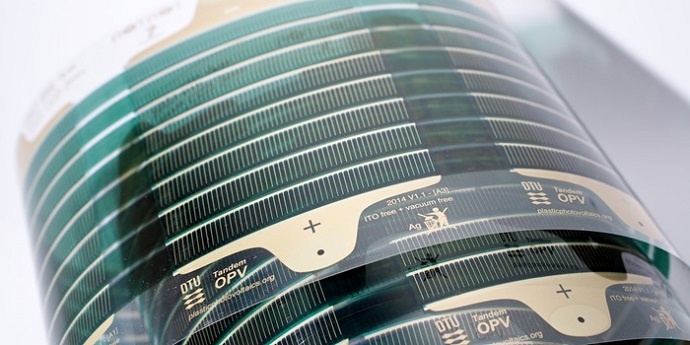

Researchers at DTU Energy Conversion are now able to manufacture multilayer plastic solar cells with the potential to capture more energy from the sun, thus making the technology financially viable.

Huge rolls of solar cells printed on plastic are just one of the suggestions for how we can collect energy in a future free from fossil fuels. Plastic solar cells are inexpensive to manufacture and the process is very straightforward. They are also flexible and can be adapted to suit almost all surfaces.

Nevertheless, they present researchers with a variety of challenges. The most significant of these is that they utilize less of the energy from the sun than conventional units. Researchers at DTU are attempting to address this issue, and a recent breakthrough has given them grounds to hope they can achieve a level of efficiency that will make the technology financially viable.

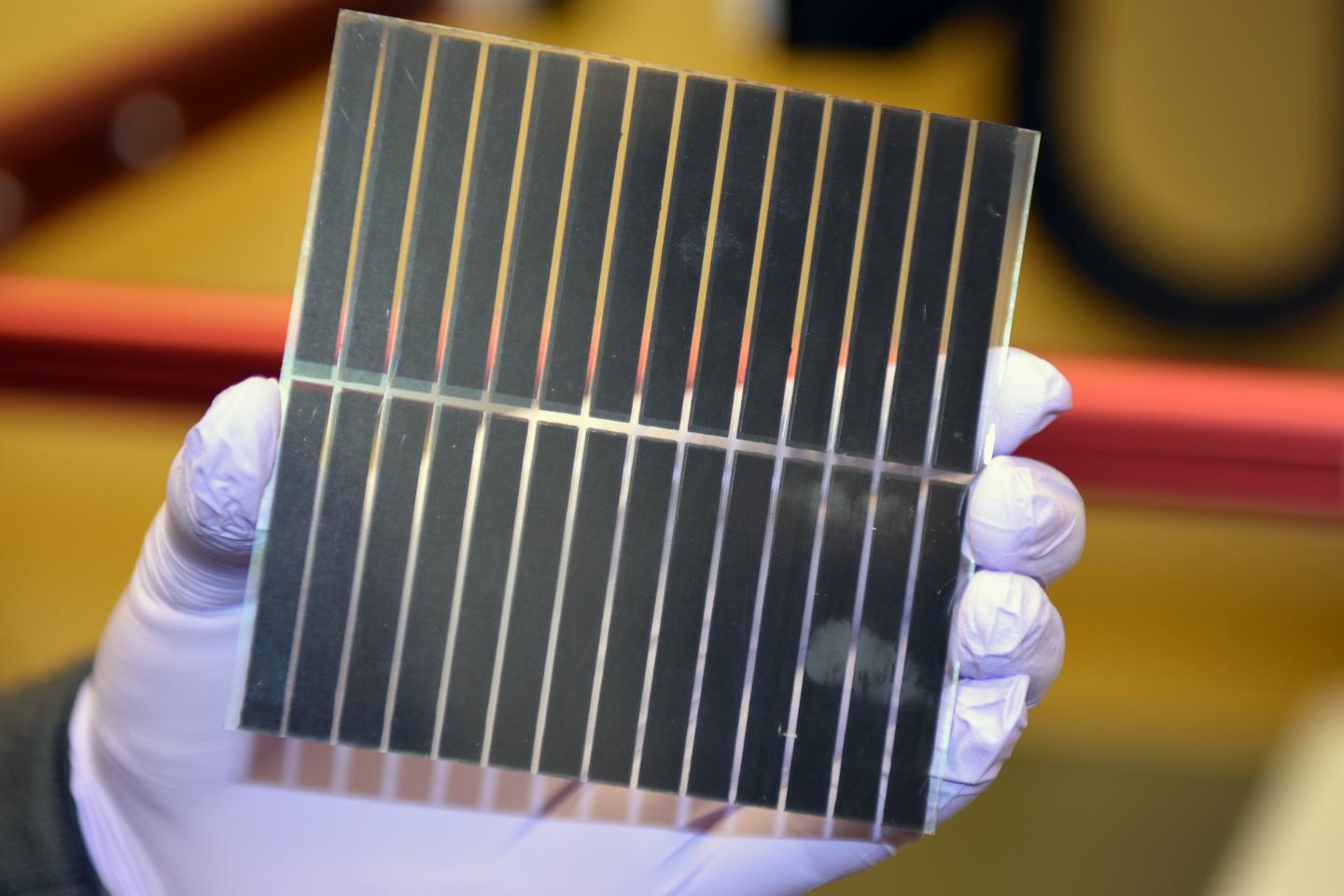

“When it comes to making plastic solar cells, the challenge is that each material only has a relatively limited spectrum in which it can absorb light. We have therefore started to make ‘tandem solar cells’, which involves positioning layers of solar cells with different properties on top of each other. One layer absorbs a specific part of the spectrum, and then the remaining light passes through it to be captured by the next layer,” explains Jens Wenzel Andreasen, Senior Researcher at DTU Energy Conversion.

“It sounds very simple, but it makes the solar cell much more complex because you have to have an extra layer between the two layers of cells to deal with the released charges that are to produce current. Another problem is that you have to make sure not to damage the layer you have just made when you position a new layer on top of it.”

The reason for this is that the polymers used to make solar cells have to be mixed with a solvent so that they can be printed—and the same solvent is often used for the different polymers. As a result, the first layer is often dissolved when the next layer is printed.

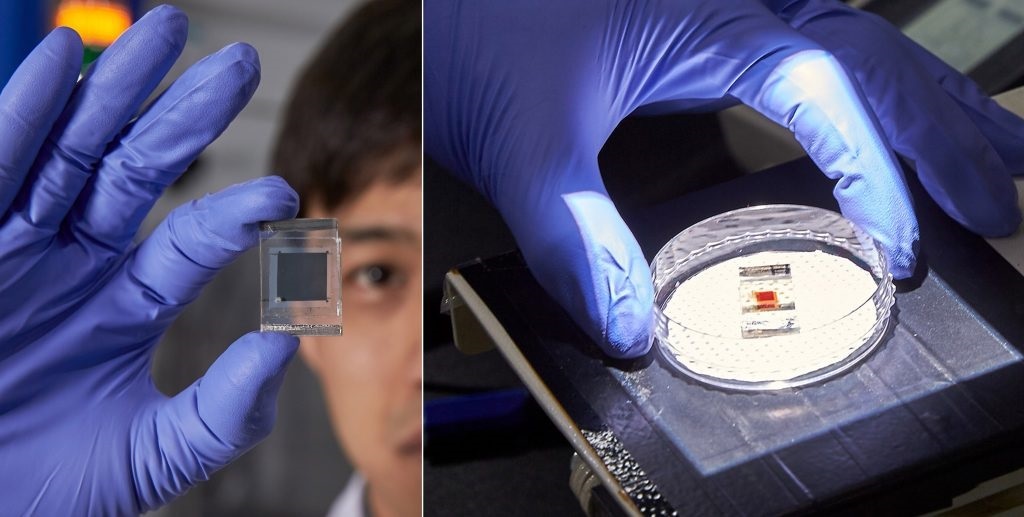

However, Jens Wenzel Andreasen and his colleagues have come up with a solution: by adding a layer of zinc oxide and conductive polymers, they can ensure that the charges are controlled, and that the underlying layer does not dissolve when a new layer is applied. Even though the layer of zinc oxide is only 40 nanometres thick, a test performed on the German x-ray synchrotron DESY has demonstrated that—in combination with the thin layers of conductive polymers—it constitutes an effective barrier against the solvents.

For their experiment, the researchers used what is known as ‘3D ptychography’—an x-ray technology that makes it possible to reconstruct the shape and chemical composition of the solar cells in detail. The technology provides much higher resolution than conventional x-ray technologies can even approximate, allowing the researchers to see that the layer of zinc oxide—just 40 nanometres thick—was intact and functioning as intended. The result was a tandem solar cell able to convert 2.67 per cent of energy from the sun into current.

“We can now use the technology to see exactly what’s happening in the plastic solar cells, and we have found a way of printing one layer on top of another without damaging anything. This means we’re better able to control the structures in the cell, which will inevitably lead us to higher efficiency,” explains Jens Wenzel Andreasen.

Article in DTUavisen no. 9, November 2014.