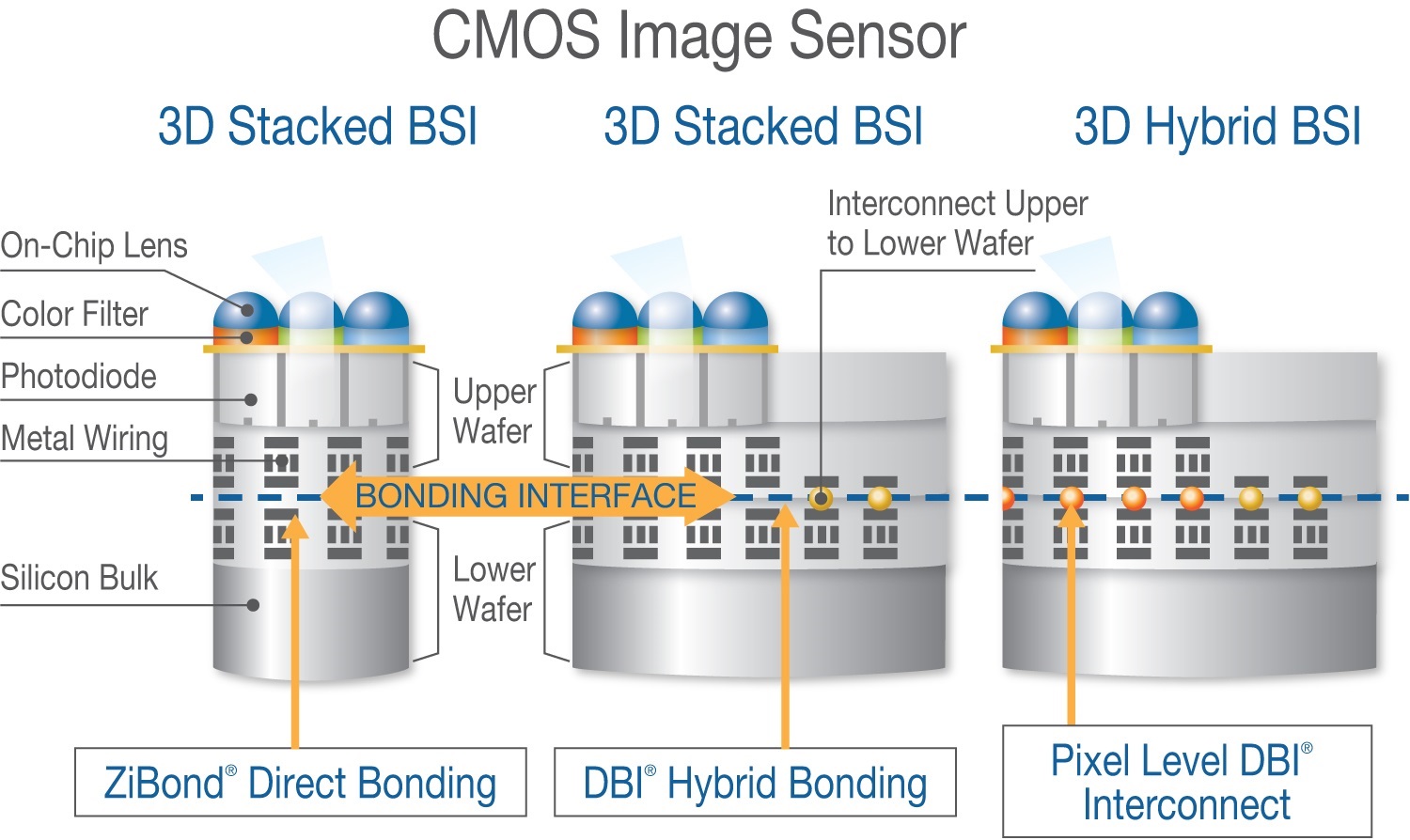

SAN JOSE, Calif. and MIGDAL HAEMEK, Israel, June 10, 2020 – Xperi Holding Corporation (NASDAQ: XPER) (“Xperi”) and Tower Semiconductor (NASDAQ/TASE (“Tower”), a global leader in high-value analog semiconductor foundry solutions, today announced Tower’s license of Invensas ZiBond® and DBI® 3D semiconductor interconnect technologies. This technology complements Tower’s manufacturing of its state of the art stacked wafer BSI sensor platforms for time of flight (ToF), industrial global shutter and other CMOS image sensors on 300mm and 200mm wafers. In addition, Tower Semiconductor will explore the use of Invensas enabling 3D integration technologies for a broader range of applications, including memories and MEMS devices.

“With our fast portfolio expansion, Xperi’s leadership in direct and hybrid bonding technologies enables us to support the rapidly evolving requirements of our customer base as they develop next-generation applications,” said Dr. Avi Strum, Senior Vice President and General Manager of the Sensors Business Unit, Tower Semiconductor. “3D stacking architectures and integration are core to our strategy of providing the highest value, proven analog semiconductor solutions, including event-driven and time of flight sensors for mobile, automotive, industrial and high-end photography applications.”

With the recently released full design kit for hybrid bonding, Tower’s customers can now design their products on two different wafers, an imager wafer and a mixed-signal CMOS wafer, that are then stacked together with electrical connections on a pixel level, from 10um pitch for applications such as Direct ToF (dToF) and event-driven sensors, down to 2.5um and even below for applications such as mobile ToF for face recognition applications. This separation into two wafers allows very high speed circuitry on the CMOS side, with very high sensitivity pixels, due to backside illumination, and extremely low dark current, below 1 electron/sec per square micron at 60 degrees Celsius, on the imager side. Tower’s unique platform also allows the use of different Epi thicknesses for near infrared sensitivity enhancement.

“Tower Semiconductor continues to strengthen its position as a leading and trusted analog foundry partner of customers around the world,” said Craig Mitchell, President of Invensas, a wholly owned subsidiary of Xperi. “Our ZiBond and DBI technologies support the manufacturing of a wide range of devices. We are excited to partner with Tower Semiconductor to deploy our foundational 3D integration technologies into a range of new sensors, in particular time of flight sensors, which we anticipate will be increasingly utilized in automotive, mobile and industrial applications. This partnership continues the strong momentum Xperi has enjoyed as manufacturers worldwide position themselves to address an evolving range of industry needs.”

Industry momentum is building around 3D semiconductors that are smaller, thinner and higher performance to enable a new wave of applications for automotive, industrial, Internet of Things, edge computing and consumer device markets. Invensas has achieved fundamental advances in the semiconductor packaging and interconnect technologies required to create 3D stacked chips that satisfy demanding size and performance requirements. Invensas ZiBond direct bonding technology and DBI hybrid technology are ideal for high-throughput, low cost-of-ownership fabrication processes.