October 4, 2018

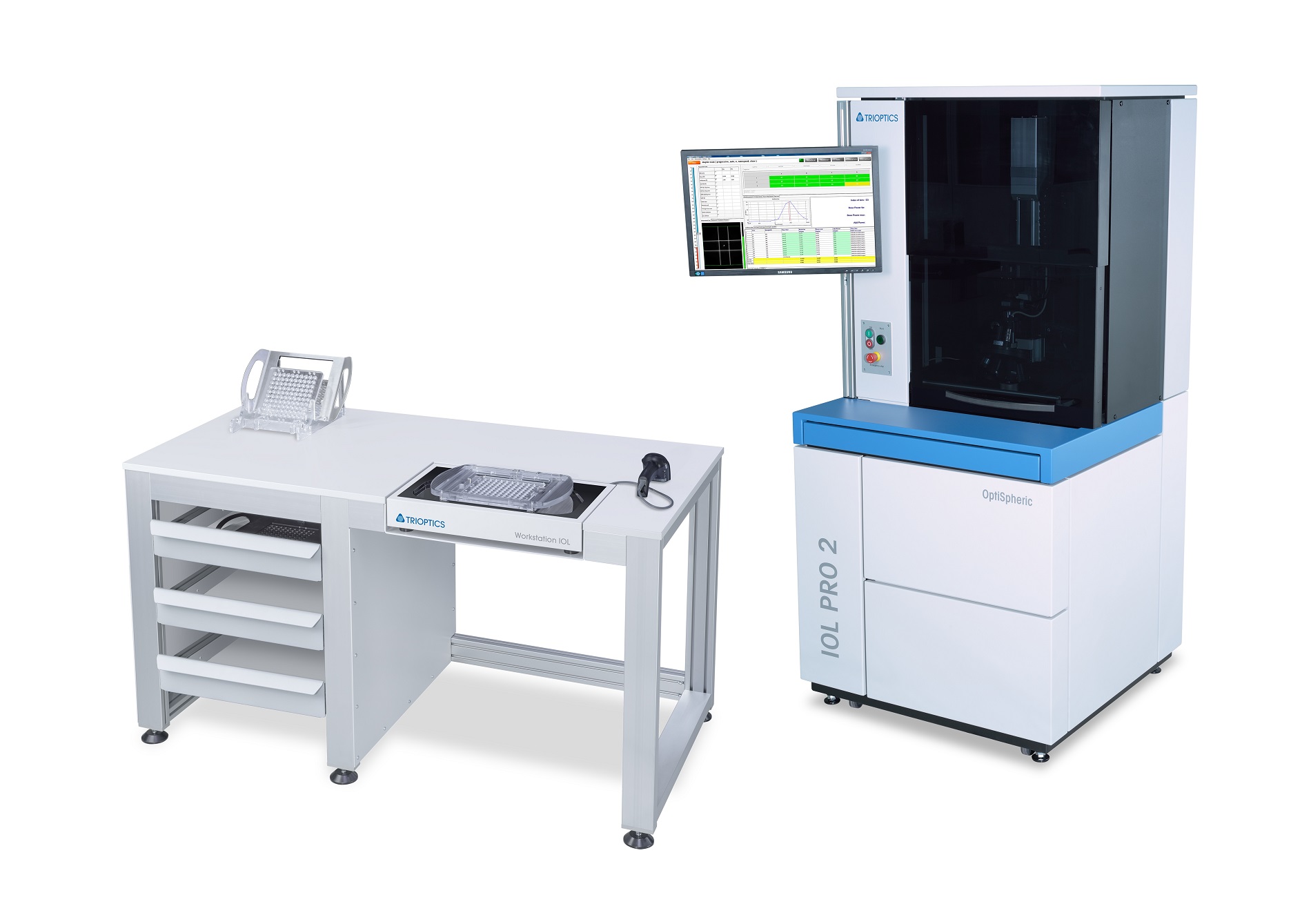

For many years, the OptiSpheric® IOL PRO 2 made by TRIOPTICS has been a well-established instrument for the quality control of multiple intraocular lenses (IOL) in one single operating sequence. OptiSpheric® IOL PRO 2 is a fully automated test system designed and optimized for use in production. It measures all optical parameters in compliance with the ISO 11979 standard. Whereas the IOL measurement is fully automated, the sorting of the lenses is carried out manually. To facilitate this manual step, TRIOPTICS presented its Workstation IOL at the 2018 ESCRS for the first time as a workplace that complements the OptiSpheric® IOL PRO 2.

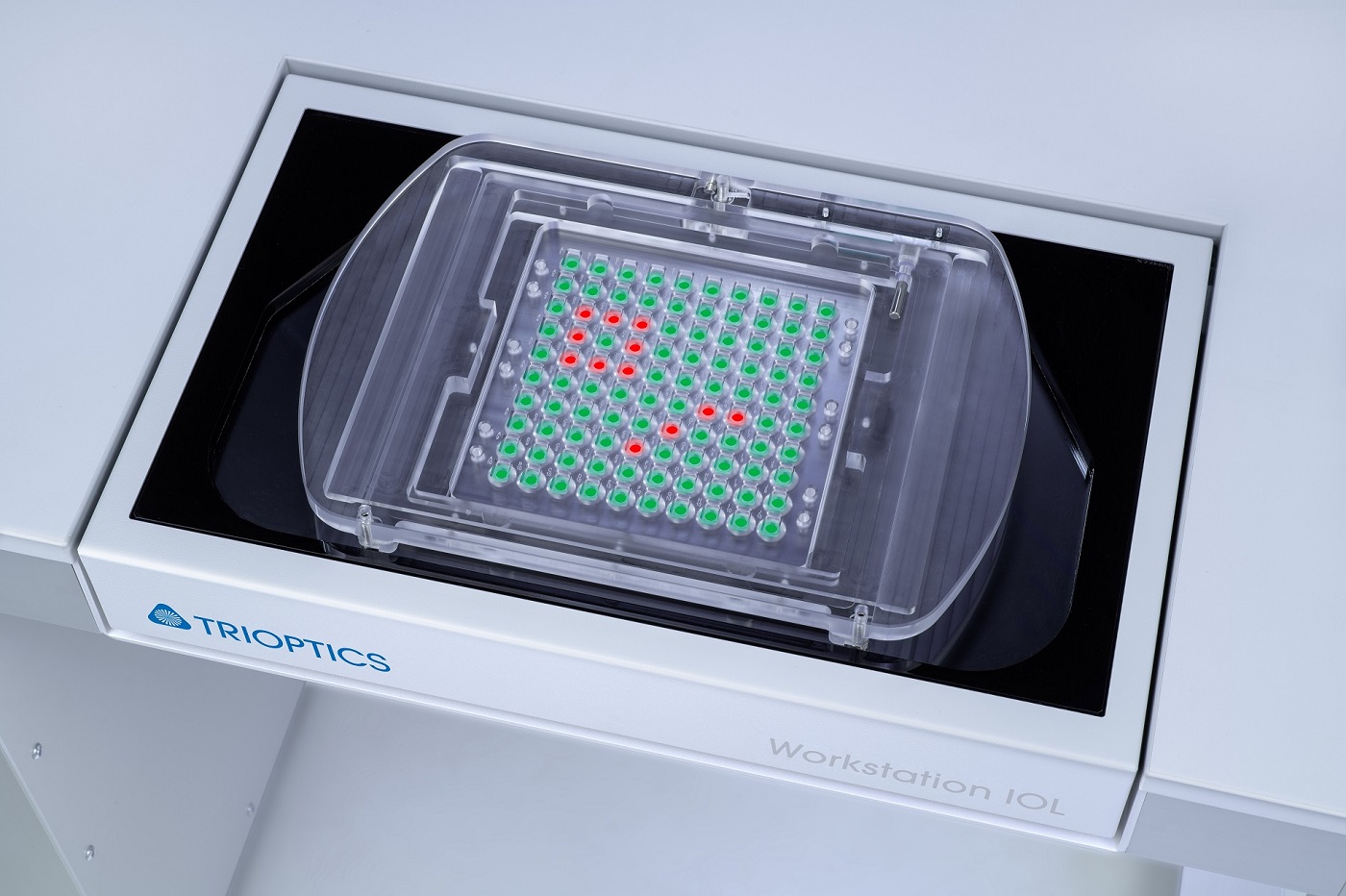

The test result of the OptiSpheric® IOL PRO 2 is displayed and thus facilitates sorting of the IOLs.

The Workstation IOL’s main feature is a display that indicates for each lens if the quality inspection has been passed. “After the measurement process, the test results are automatically transmitted to the customer’s database and to the display,” explains Product Manager Dörte Zimmermann. “Before that, the sample tray is identified via a barcode scanner to prevent mix-ups. A red and green color scheme indicates if a lens has passed or failed. This makes sorting easy, quick and, above all, reliable.”