February 8, 2018

UNIVERSITY PARK, Pa. — Producing the perfect color images we need and love often requires multiple, heavy lenses so that each color focuses in exactly the same plane. Now Penn State engineers have developed a new theory that solves the problem using a single thin lens comprised of gradient index materials and metasurface layers to properly direct the light.

"If we want high performance optical systems, then we have to overcome material dispersion," said Sawyer D. Campbell, assistant research professor in electrical engineering. "If we don't, we get smeary colors, which significantly degrades image quality."

Single apochromatic lenses — ones that properly focus the three colors red, blue and green — that have less curvature and are thinner and lighter could improve cell phone cameras and allow manufacture of thinner cell phones. They also could make lighter, better body cameras, helmet cameras, sniper scopes, thermal imaging devices and unmanned aerial vehicles or drones. In essence, anything that uses lenses to image could be made simpler and lighter.

"Usually there are several lenses, but that increases the weight," said Jogender Nagar, graduate student in electrical engineering. "Our aim is to improve SWaP — reduce size and weight while increasing performance."

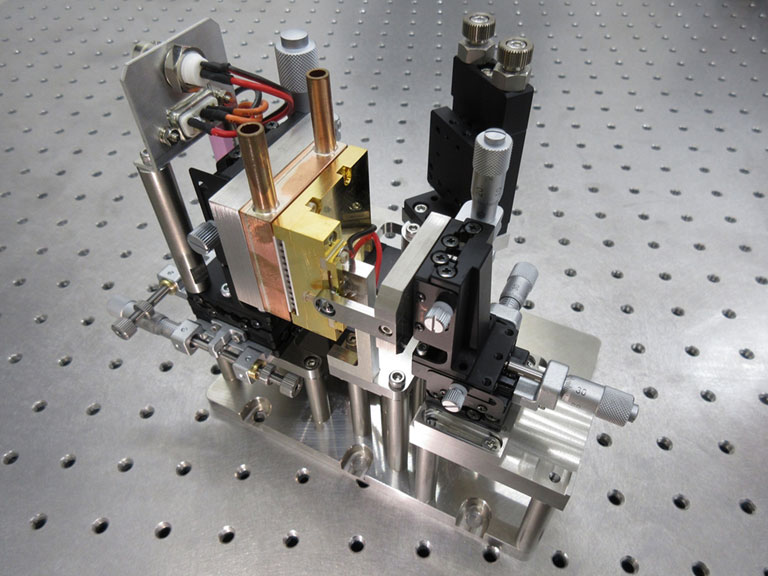

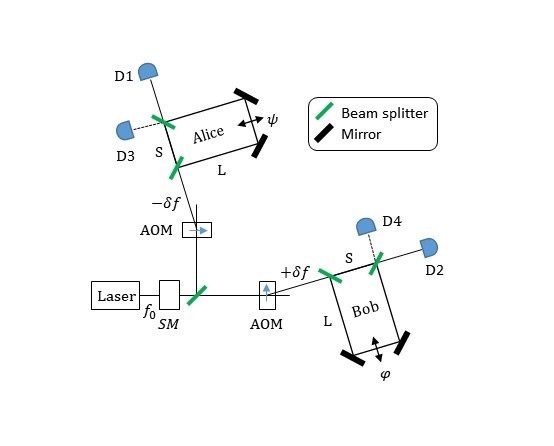

The researchers thought to combine two technologies: that of gradient-index (GRIN) lens, and metasurfaces — ultra-thin optical layers with sub-wavelength features that manipulate the wavefront in a desired manner. The researchers report the results of their work in the current issue of Optica.

"Our system uses one lens," said Nagar. "We use the curvature of the lens, the distribution of materials in the lens, and a metasurface — a pattern placed on the surface — to make the lens thinner, lighter, but still focus properly."

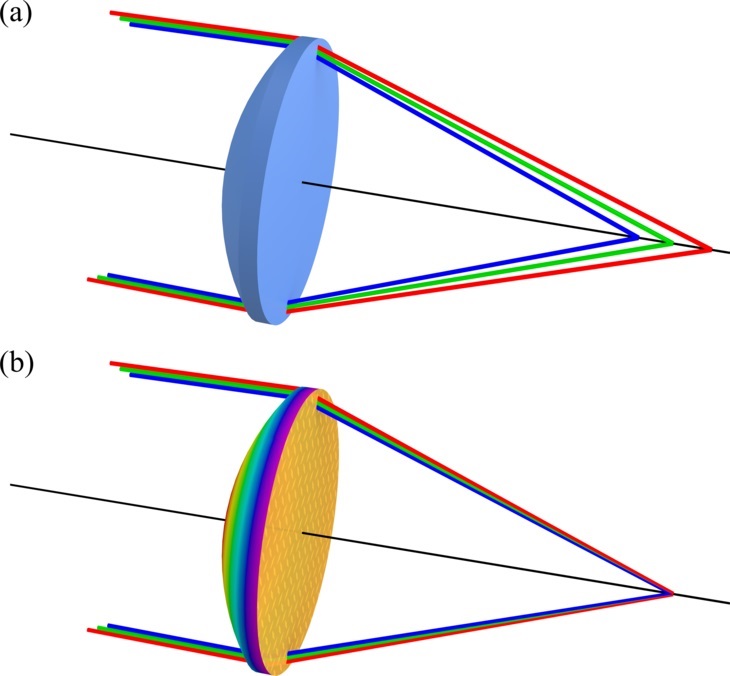

Most lenses use curvature to control the focal point, but three separate conventional lenses are needed to focus the three separate colors to one focal point and produce a high quality image. By spatially varying the material composition inside the lens, one GRIN lens can perfectly focus two colors. Then, by adding a metasurface to the GRIN lens, one layered lens can perfectly focus all three colors and do the work of three conventional lenses.

"The gradient in the lens can be axial — varying along the direction of light propagation, or optical axis; or radial — varying outwardly from the optical axis," said Douglas H. Werner, John L. and Genevieve H. McCain Chair Professor in electrical engineering. "Or it could be more complex."

The researchers developed a theoretical model and simulation framework for creating these lenses.

"We had to use some advanced tools that were specially developed in the lab," said Werner. "Tools for modeling, simulation and optimization that we created for solving such a challenging design problem."

The theoretical model specifies the proper surface curvature and gradient in the GRIN lens and the proper patterning for the metasurface to satisfy the requirements of perfect focusing of all three colors. The model optimizes both the lens and the metasurface to work together.

"The theory is very general and covers a wide range of conditions," said Werner. "Fabrication will be the challenge initially. We hope development of the theory will steer the fabrication, making it possible to produce such lenses at a low cost and high volume."

The Defense Advanced Research Projects Agency supported this work.