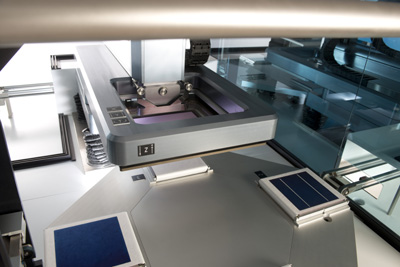

SHANGHAI, April 23, 2015 – Ahead of the SNEC International Photovoltaic Power Generation Exhibition being held next week, Applied Materials, Inc. today announced its Applied Tempo™ metallization system that is setting new efficiency, high-productivity and low-cost benchmarks for manufacturing advanced high-efficiency cell designs. Supporting Applied's unique Fine Line Double Print™ (FLDP) technology and record throughput, the Tempo platform delivers substantial efficiency, yield and cost benefits that translate into the industry’s lowest cost of ownership and lowest overall cost-per-watt solution for cell manufacturing.

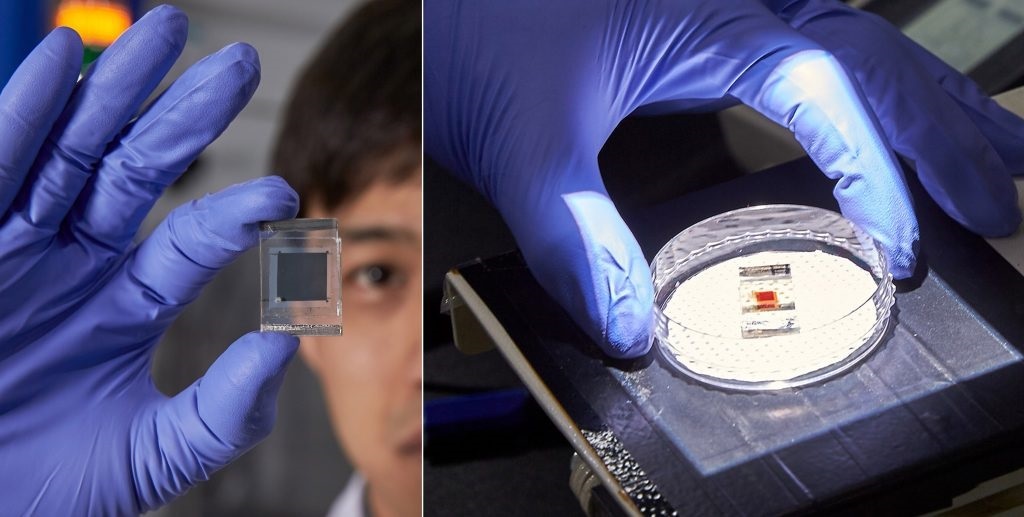

New Tempo platforms are successfully being used today by multiple PV manufacturers worldwide. Among the first customers to run the platform in high-volume production is JA Solar Holdings Co., Ltd., one of the world's largest manufacturers of high-performance solar power products.

"We are very pleased to collaborate with Applied Materials as we focus on manufacturing our future cell designs," said Dr. Wei Shan, CTO of JA Solar. "The new Tempo system requires fewer operators than any other metallization platform, yet still delivers exceptional Fine Line Double Printing, throughput and yield performance, which are critical requirements for us to meet market demand for higher efficiency cells. We were able to quickly implement double printing to enhance cell efficiency and, with the platform’s dual lane configuration, achieve output in excess of 75,000 cells per day. Based on these advantages and the platform’s low cost of ownership, JA Solar looks forward to working with Applied on further solutions to advance solar cell technology."

"We are delighted JA Solar, one of the most respected and established technology leaders in China, is benefiting from the advanced metallization capabilities of the Tempo system in production. JA Solar is improving cell efficiency using our Fine Line Double Printing technology and achieving record high daily throughputs at the same time," said Jim Mullin, vice president and general manager of Solar Products for Applied Materials’ Energy and Environmental Solutions Group. "These are important advantages to keep pace with the 10 Watt per year ‘efficiency clock’ driving the PV industry. We're honored that an industry leader such as JA Solar has chosen Applied's precision materials engineering technologies to meet its cell performance, yield and cost needs."

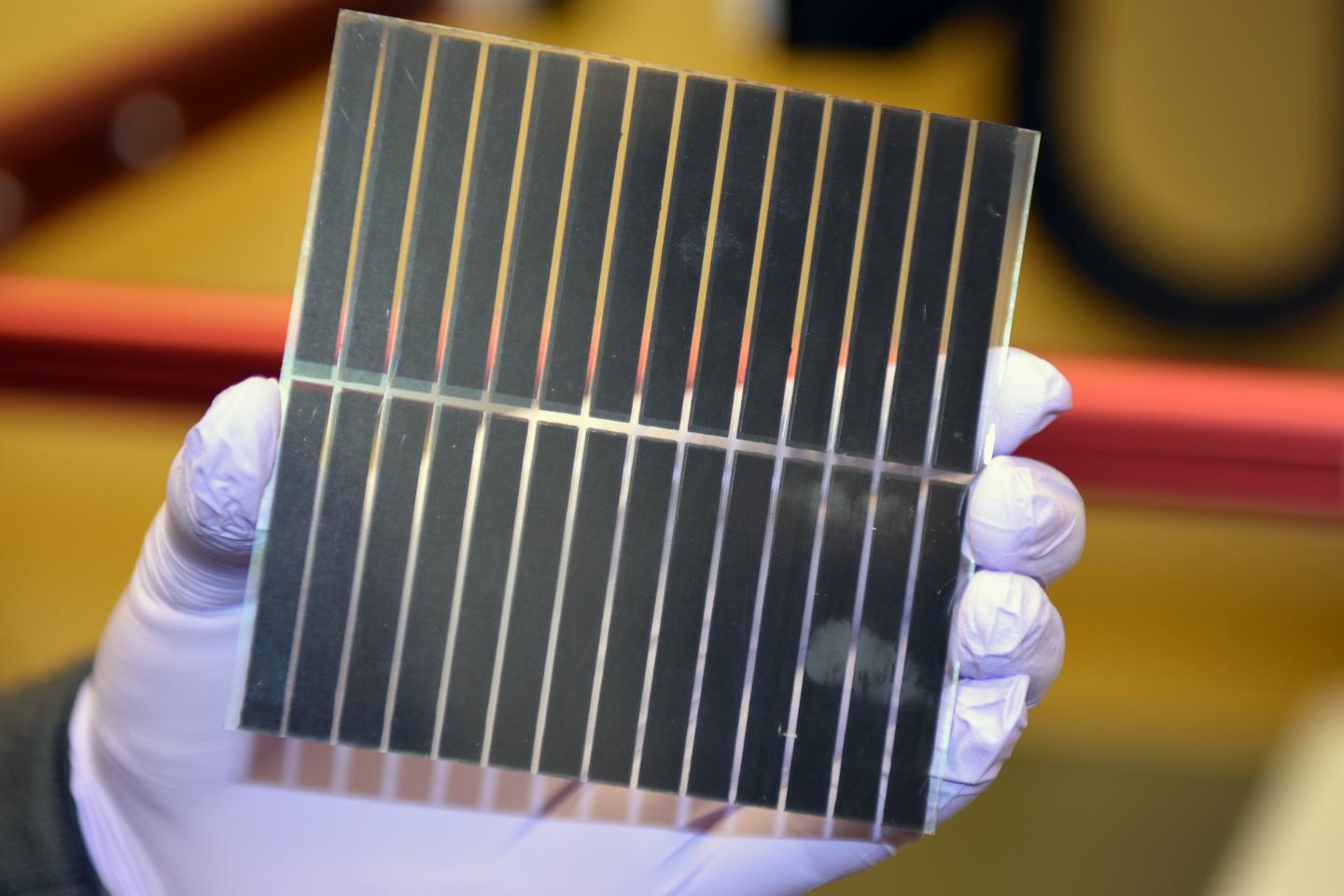

The Tempo platform’s groundbreaking performance builds on the proven technologies of Applied’s metallization platforms. These include FLDP that reduces resistivity and shadowing to deliver a 0.2% gain in cell efficiency. FLDP optimizes the conducting lines of a solar cell by making them taller and narrower, increasing cell efficiency while simultaneously reducing expensive silver paste usage. Also important, by reducing breaks in the metal lines, FLDP can help increase yield. Sophisticated handling and high speed control allow the Tempo platform to run at more than 3,200 wafers per hour without impacting printing process and quality.

Applied Materials, Inc. (Nasdaq:AMAT) is the global leader in precision materials engineering solutions for the semiconductor, flat panel display and solar photovoltaic industries. Our technologies help make innovations like smartphones, flat screen TVs and solar panels more affordable and accessible to consumers and businesses around the world. Learn more at www.appliedmaterials.com.