March 15, 2018

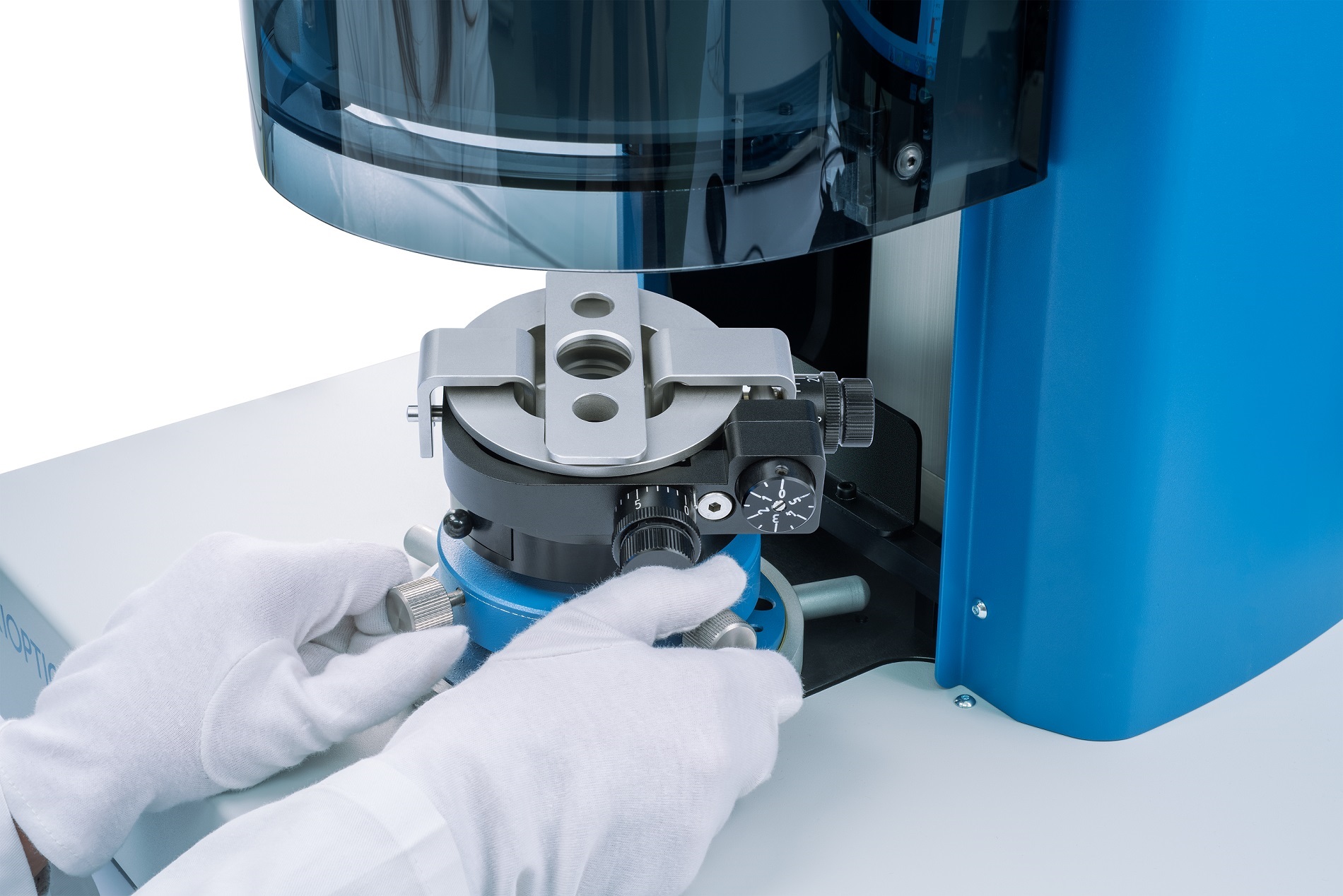

With the new OptiSpheric® IOL R&D, TRIOPTICS GmbH offers the ideal system for testing state-of-the-art intraocular lenses during research and development in accordance with ISO 11979.

IOL manufacturers are continuously developing new lens models to meet the latest technological standards. TRIOPTICS now offers the perfect solution for putting these new products to the acid test in compliance with ISO 11979: the new OptiSpheric® IOL R&D.

Especially designed for research and development, the OptiSpheric® IOL R&D impresses with its flexibility. The device can be used to measure and test important parameters of all modern lens designs (monofocal, multifocal, trifocal, toric, aspheric and those with extended depth of focus (EDOF) – whether diffractive, refractive, or sectors), such as refractive power, modulation transfer function and MTF focus scan, orientation and orthogonality of the cylinder axis of toric lenses, radius of curvature, and back focal length. The manufacturing quality can also be visually assessed via the built-in camera. “The design of the device meets all the requirements of ISO 11979 – including an integrated real cornea,” emphasizes product manager Dörte Zimmermann. “Therefore, all evaluations of the newly developed IOL can be conducted in compliance with the standards.”

OptiSpheric® IOL R&D is optimized for use in research and development during intraocular lens research and development.

In addition to the testing procedures described in the standard and the pre-programmed test processes, the software also supports individual, user-defined measurements. “This gives the customer complete control over which parameters are measured and how,” explains Zimmermann. “These test processes can also be easily stored for use at a later point, for example to repeat the tests on other lenses or under different conditions.”

To ensure that the lenses also meet the real-world requirements for the patient’s eye, the OptiSpheric® IOL R&D offers flexibility in the use of various corneas and filters. “Both spherically aberrated corneas and lighting filters for 644 nm, 546 nm, 480 nm and photopic illumination simulate real imaging conditions,” Zimmermann says. The perfect positioning is not always achieved during the implantation of the lenses. The effects of such relevant, practice-oriented displacements and tilting can be simulated with the Model Eye R&D. The results can help to optimize the lens design, even in the case of incorrect positioning.

Since both the measurement method and the software are based on the OptiSpheric® IOL PRO 2 system, the results for the pass/fail analysis and the necessary measurement processes can be easily transferred from development to the quality control of the series production. This facilitates the initial evaluation processes in production and ensures the comparability of all results.