October 19, 2017

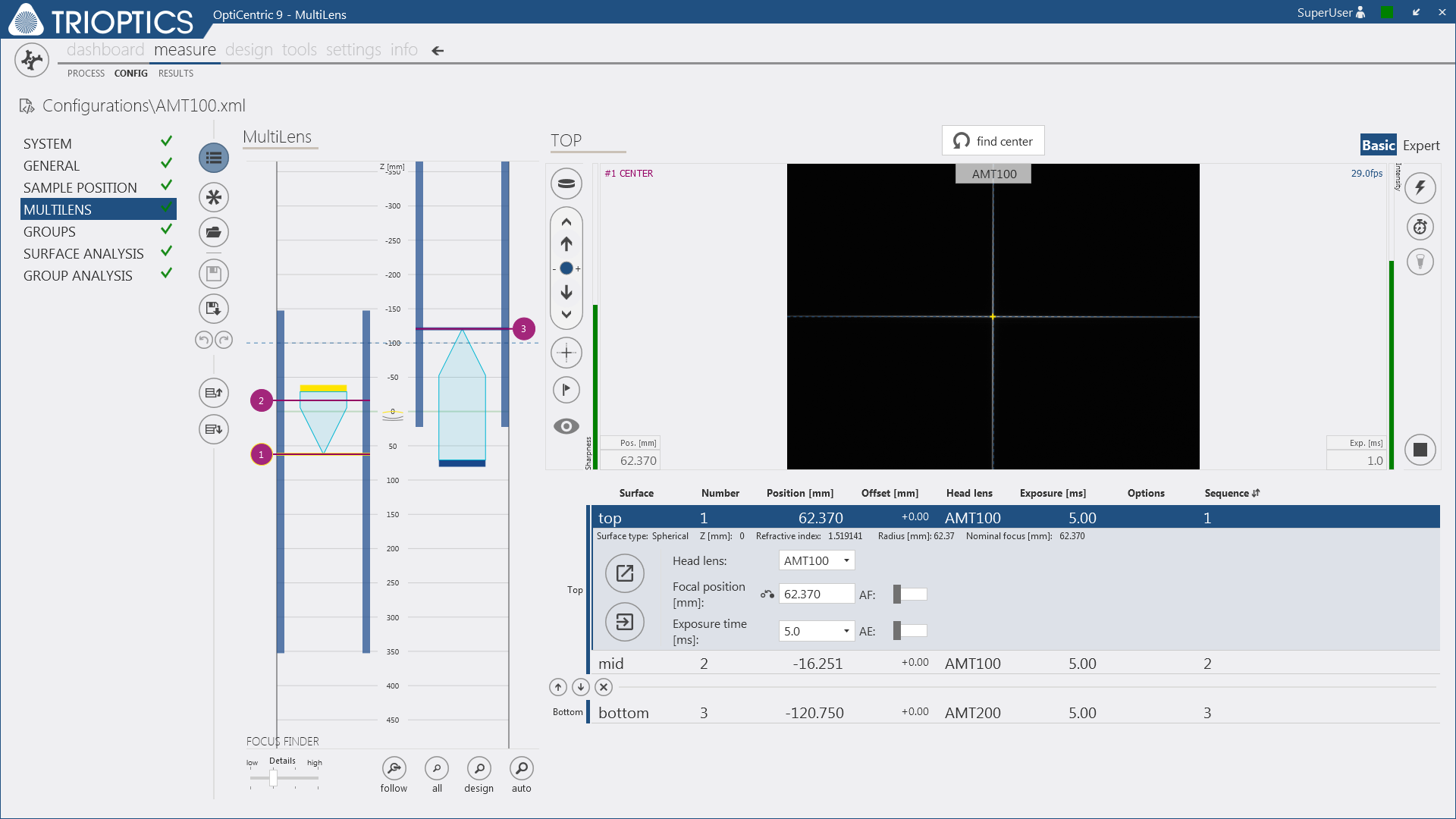

TRIOPTICS GmbH, a leading manufacturer of optical measurement and testing instruments, now presents new software for its established OptiCentric® lens centering system. The software makes it possible to optimize work processes, particularly in production, and to efficiently perform comprehensive tests in R&D.

The lens centering technology with TRIOPTICS OptiCentric® has long been established in optical workshops worldwide. Over the years, the range of functions and features has been expanded and today, the system offers options that extend beyond just lens centering measurements in the laboratory. There are several tools available which extend the OptiCentric® functionality from bare lens centering quality assessment to automated lens alignment functions. For example, active alignment processes for doublet cementing and glue bonding into lens cells are supported. In this respect, the OptiCentric® lens centering technology is generally playing an increasingly important role in both series testing and objective lens production.

However, the requirements regarding the design of the software also change in line with the processes being performed. The challenge is to map the necessary scope of functions without making any compromises. Therefore, the software is carefully designed to optimally guide the operator through the process and to limit the available options to only the process specific ones. With this aim in mind, TRIOPTICS invested a great deal in the development of an user-friendly and intuitive new software for the whole OptiCentric® system family.

“The new software has a linear structure,” explains Product Manager Dr. Patrik Langehanenberg. In detail, this means that the user is guided step by step through a predefined measuring process. In addition, the software offers a number of support programs and the process and results are continuously checked for plausibility. Langehanenberg adds: “The software makes even very complex workflows, procedures and processes more easily accessible, for less experienced staff as well. Nevertheless, it can be ensured that all measuring, cementing and bonding processes run properly and completely, independent of the user.”

The new software, which is comprehensive and yet greatly simplified in terms of usability, will be presented at the SPIE OptiFab 2017 exhibition in Rochester, New York (USA). Visitors to the exhibition are able to experience first-hand the process-based program for combined centering and center thickness measurements, the precise alignment and cementing process for a lens on an arbor, and for automated asphere measurements.