SCHOTT unveils SCHOTT RealView™, a breakthrough in high-index glass wafers that allows more immersive augmented reality (AR) applications. These new wafers are made from optical glass with a high refractive index, enabling a wider field of view (FOV) in AR devices. The geometrical precision of the wafer surface is controlled to unprecedented accuracy, creating superior picture quality with the best contrast and highest definition, enhancing the user experience. SCHOTT is positioned as a global leader in AR materials with its unique fully integrated manufacturing capabilities, its 133 years of leadership in the mass production of optical glass, and its capabilities in high-index wafer and tailored optical coatings. Experts from SCHOTT’s Advanced Optics Team will be available to discuss AR glass in booth 1045 at Display Week 2018 in Los Angeles, California from May 22 to May 24.

Los Angeles, Calif. – May 16, 2018 – Smart glasses need smart glass. SCHOTT, the international technology group, has developed optical glass wafers for augmented reality (AR) applications – branded as SCHOTT RealView™ – that double the total internal reflection angle compared to conventional glass wafers, enabling a larger field of view (FOV) in AR devices. SCHOTT RealViewTM wafers give AR device manufacturers the first opportunity to expand the FOV almost to the limit of human peripheral vision. This innovation lays the groundwork for sizeable advances in this transformative consumer tech field. SCHOTT produces raw glass in its high-tech melting facilities in Germany, and the wafer manufacturing and optical coating takes place in China, where SCHOTT recently announced a joint venture investment together with Zhejiang Crystal-Optech. With core competencies in innovation and scaling to mass production, SCHOTT is the preferred partner in the field of AR.

Redefining AR experiences with outstanding glass

“Augmented reality should still look like reality,” said Dr. Rüdiger Sprengard, Vice President and Head of Augmented Reality, Advanced Optics at SCHOTT. "To raise the bar and meet the requirements of this rapidly expanding market, manufacturers need superior optical wafers with qualities a full order of magnitude greater than what has previously appeared on the market - a challenge SCHOTT scientists and engineers have accepted in the spirit of pushing the limits of process technology and metrology."

Over the past few years, researchers at SCHOTT have leveraged their expertise in melting and surface processing of optical materials while working alongside AR technologists to understand the needs of the industry. Today, from intense work on design, prototyping, and processes proven in mass production, the tailor-made optical glass solution for AR has become a reality: SCHOTT RealView™.

“We have the advantage of being a fully integrated supplier, covering every step of the process to control properties that are key to the quality of the image: glass melt, wafer processing, and optical coatings,” said Dr. Sprengard. “We have invested in the infrastructure to ensure we’re fully capable of ramping-up production to meet demand.”

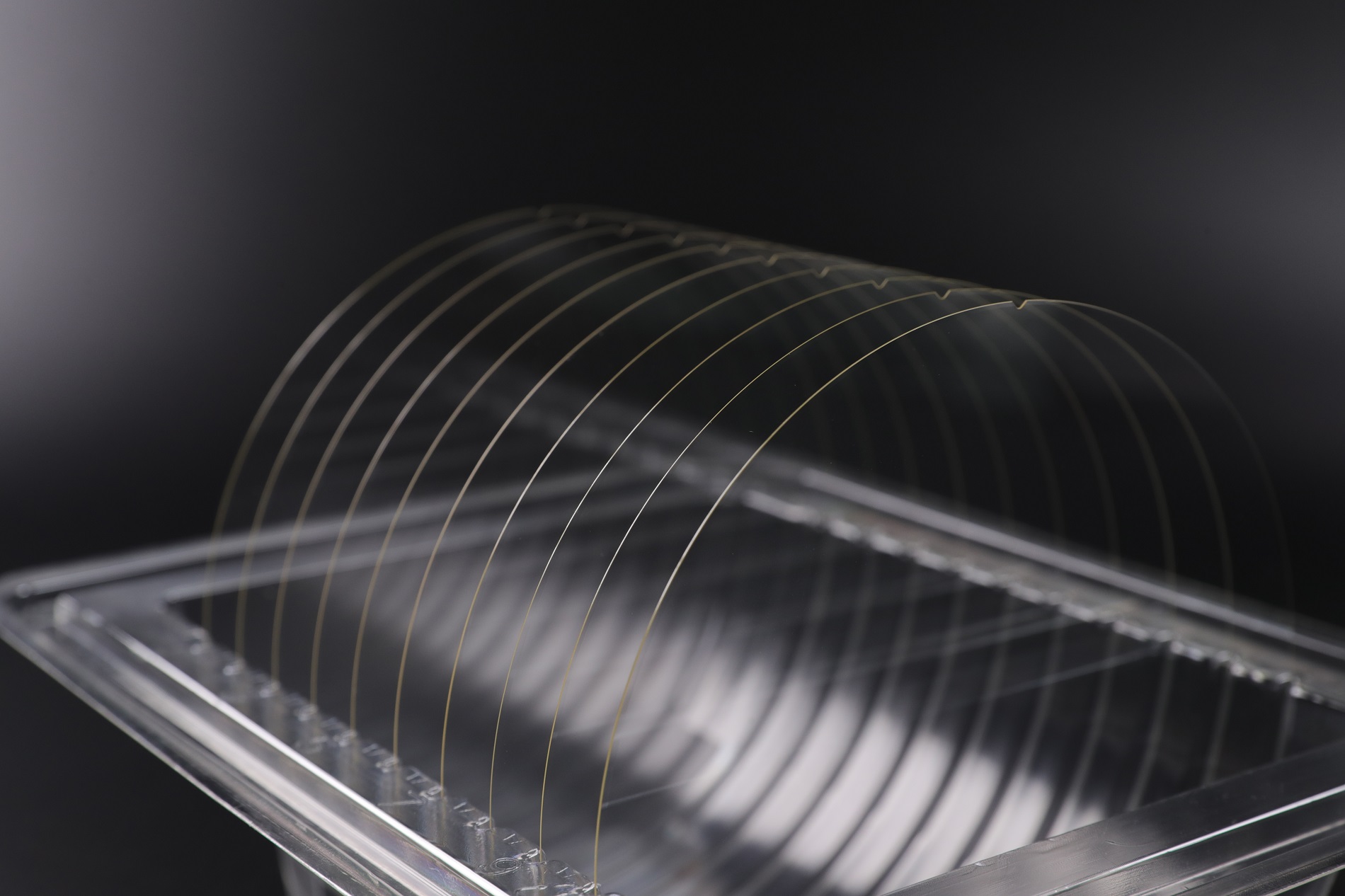

SCHOTT RealView™ glass wafers are made from optical glass with a high refractive index, enabling a wider field of view (FOV) in AR devices. Photo: SCHOTT

Optical glass refined to SCHOTT RealView™ glass wafers

SCHOTT RealView™ glass wafers are available with tailored refractive index and excellent light guiding properties. As a result of engineering innovation, SCHOTT RealViewTM is 10 times flatter, measured as Total Thickness Variation (TTV), than industry standard glass wafers.

AR customers will benefit from the unique combination of SCHOTT's 133-year world-class heritage in optical glass and expertise in processing. SCHOTT’s production facilities in Germany have a long history of producing high-quality glass materials, with a portfolio of 120 optical glasses with refractive indexes up to 2.0. The company shares its expertise to help developers select the right material to meet their specifications. SCHOTT is capable of mass-producing materials for blockbuster products in China. For prototyping and research, customers can rely on SCHOTT’s expertise in glass, wafer processing, and coating in its German and Swiss facilities. SCHOTT is prepared to fuel the growth of the emerging AR industry.

https://www.us.schott.com/reality/