August 7, 2017

In a recent paper in Light: Science & Applications, University of Rochester researchers Jannick Rolland and Jacob Reimers describe an optical device with potential applications ranging from improved satellite and diagnostic imagery to more precisely matching the paint color on a living room wall.

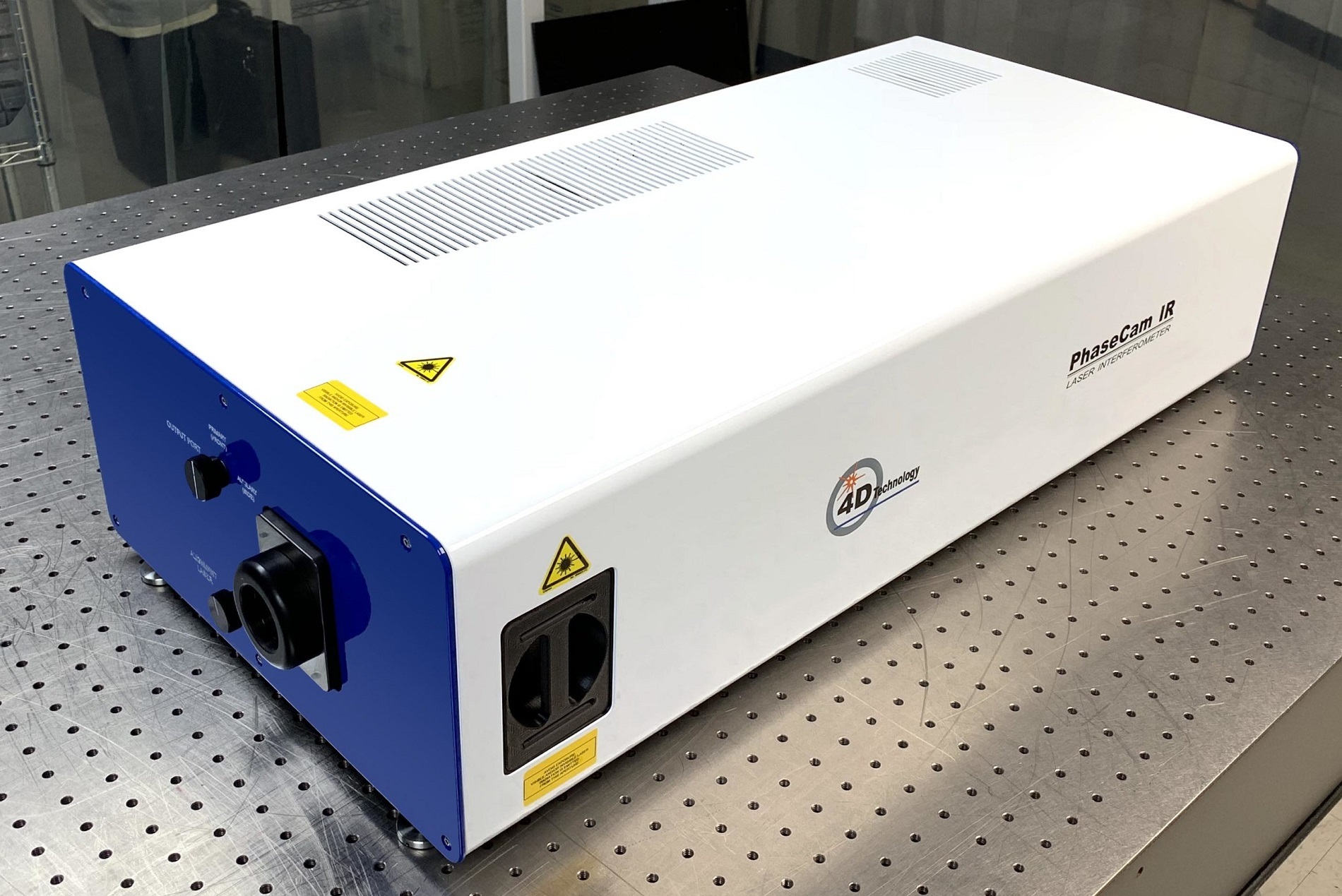

The device is a type of spectrometer—an optical instrument that takes light and breaks it down into components to reveal a catalogue of information about an object.

Unlike traditional spectrometers, however, this one is designed using freeform optics, a relatively recent advance that upends more than a century of optical design.

For more than 125 years, optical design was constrained to using rotationally symmetrical, often perfectly spherical surfaces placed in round tubes—for example, single-lens reflex cameras and microscope objective lenses. Each lens element in such a design can contribute up to 15 aberrations that limit field of view and resolution.

The advent of computer numerical control and new diamond turning technology has made it both feasible and economical to design and fabricate far more complicated, freeform optical surfaces that dispense with rotational symmetry. Freeform design enables a device to efficiently correct aberrations with fewer, smaller lenses and mirrors. The result, researchers say, will be sensors, mobile displays, and a host of other devices that are not only smaller in size, lighter in weight, and less expensive—but also out-perform those containing traditional lenses and mirrors.

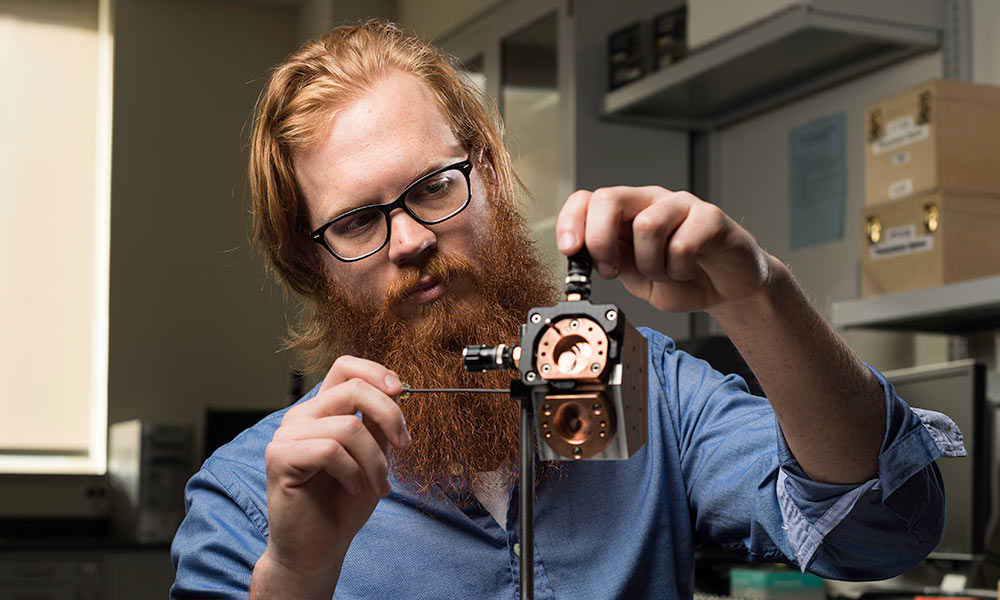

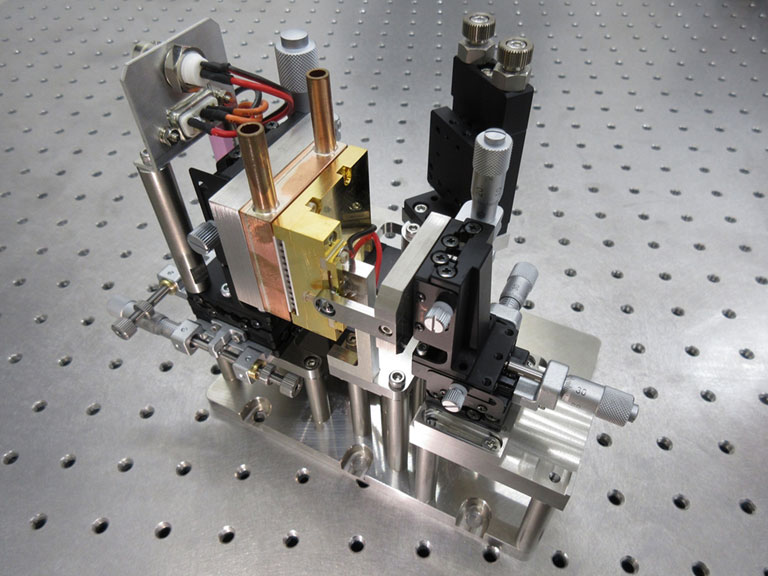

Reimers, a PhD student and the lead author, and Rolland, the Brian J. Thompson Professor of Optical Engineering and Reimers’s thesis advisor, describe a spectrometer using three freeform surface mirrors, that:

- is five times more compact than similar spectrometer designs using more conventional mirrors;

- allows a three-fold increase in the bandwidths analyzed;

- and is 65 times more effective at correcting aberrations that affect field of view and resolution.

“Spectrometers monitor the environment, help examine patients, and are broadly used for many other applications. What we found here can be applied to spectrometers used in all of these other applications,” says Rolland. “That is the power of freeform optics.”

The project is funded by the University’s Center for Freeform Optics (CeFO), a collaborative initiative funded by the National Science Foundation and directed by Rolland, which also involves the University of North Carolina at Charlotte and multiple industry partners whose membership dues fund the research. The goal of the center is to promote precompetitive projects that advance freeform optics from the laboratory to industrial applications.

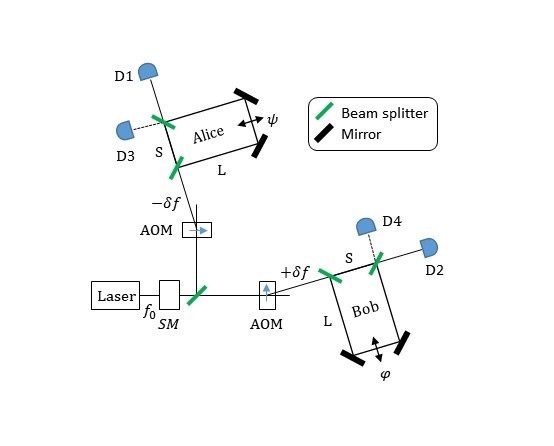

The spectrometer described by the two researchers is based on the Offner-Chrisp geometry, widely used by the optical industry to correct aberrations created by more conventional surfaces.

“Starting with an understood, well-corrected geometry was important, because we were able to show how we can make it even better using freeform optics,” says Reimers. “It is a geometry several of our CeFO industry partners endorsed.”

The paper focuses on the science behind designing a freeform spectrometer. Another paper published in June in Optics Express, an Optical Society Journal, focused on the fabrication and testing of the convex grating. Two future papers, coauthored by researchers from both Rochester and UNC–Charlotte, will describe the fabrication of the mirrors as well as the fabrication and assembly of the full prototype.

“What’s nice about what Jacob has done is to not just come up with a design, but to show the science behind it, and why it is better,” says Rolland.