January 14, 2015

Paul Alongi, College of Engineering and Science

CLEMSON — Just as the Navy was deploying a laser weapon to the Persian Gulf, a Clemson University researcher already was thinking about how to make it more powerful.

Liang Dong said the laser aboard the USS Ponce has a range of less than three miles but that the Department of Defense would like one that strikes targets more than 60 miles away.

“We’re looking at ‘Where does the next phase of technology need to go?’” Dong said.

A Navy video released last month shows the laser destroying targets mounted on top of small, moving boats. The demonstrations were done from September to November, according to the Navy.

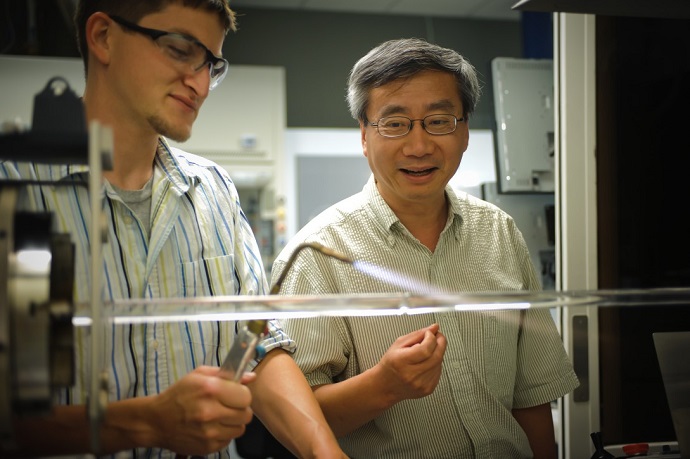

Dong’s team creates the optical fibers that go into lasers. He said that while none of his fibers were in the laser aboard the Ponce, his team is working to create an amplifier that could increase the power.

The Navy deployment makes Dong’s work particularly timely, but military lasers are only part of his research. What excites him most are the economic possibilities that come with using lasers in manufacturing.

Lasers can be used to cut, drill, weld and mark a variety of materials in ways that conventional tools cannot. Lasers, for example, are used to cut Gorilla Glass that covers smart phones.

“We see the military application, but there is also this industry revolution going on at the same time,” Dong said. “This is taking machining — cutting and drilling — to a different level.”

The Optical Society’s board of directors recently elected Dong a Fellow in recognition of his contributions to optics and photonics. The society, which has 18,500 members, allows no more than 10 percent to be fellows.

Anand Gramopadhye, dean of the College of Engineering and Science, said that Dong’s election will help raise Clemson’s international profile.

“It helps us attract top-quality students and faculty, and research dollars,” Gramopadhye said. “This ultimately leads to more homegrown innovation that gives South Carolina and the U.S. a competitive edge. Clemson is fortunate to have Liang.”

Dong is an associate professor of electrical and computer engineering. His research funding comes from a variety of sources, including the Army, Air Force and the Clemson University Research Foundation.

Creating a powerful laser for either the military or industry starts with making highly specialized glass.

Dong and his team combine various elements that are formed into a rod and put into a two-story “draw tower.” The tower strings the molten-hot glass into a fiber that looks like fishing line.

As seen through a microscope, cross-sections of the fibers show they have symmetrical patterns, some resembling honeycombs. As many as six different types of glass are embedded within each cross-section.

“It becomes a very complex puzzle to put together,” Dong said. “Everything in it has to be just right so that it will be able to support a very well-defined beam.”

Dong’s work carries on a proud Upstate tradition in lasers. Charles Townes, whose research led to the development of the laser, graduated from Greenville High in 1931 and went on to win a Nobel Prize for Physics in 1964.

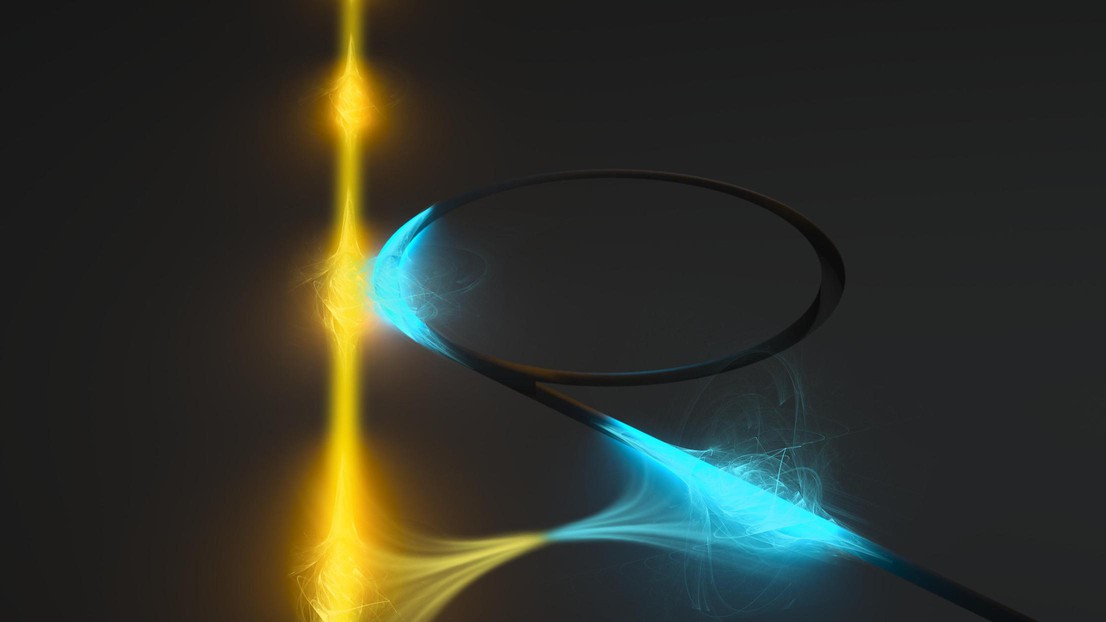

In lasers used as weapons, a low-powered laser goes through several amplifiers to increase the power. Dong and his team are developing a “last-stage amplifier,” which does the most demanding work.

In manufacturing, lasers are already surpassing conventional machining tools, Dong said.

The global market for lasers used in materials processing grew from 1.7 billion euros to 2.4 billion euros from 2005 to 2012, according to Optech Consulting. In the same period, the market share of optical fiber lasers grew from 4 percent to 18 percent.

The “Holy Grail” that Dong and other researchers are chasing is using lasers to create a more efficient fuel-injection system in a car engine, he said.

A fuel-injection nozzle is a tube drilled with very fine holes. Fuel is pressurized to form a spray into the engine. The finer the spray, the more efficient the engine.

“The key here is to drill those small holes, a large number of them in a production process in a consistent fashion,” Dong said. “If you can do this, you can make billions of dollars.”

Dan Noneaker, interim chair of the Holcombe Department of Electrical and Computer Engineering, said that Dong’s election as OSA Fellow shows the level of scholarship he brings to Clemson.

“The selection process is highly selective,” Noneaker said. “Only the top researchers in his field are elected. I congratulate him.”